Core competitiveness

Product leader

5000+

Cumulative cooperation cases

1000+

Cumulative number of service customers

TOP03

Industry satisfaction evaluation

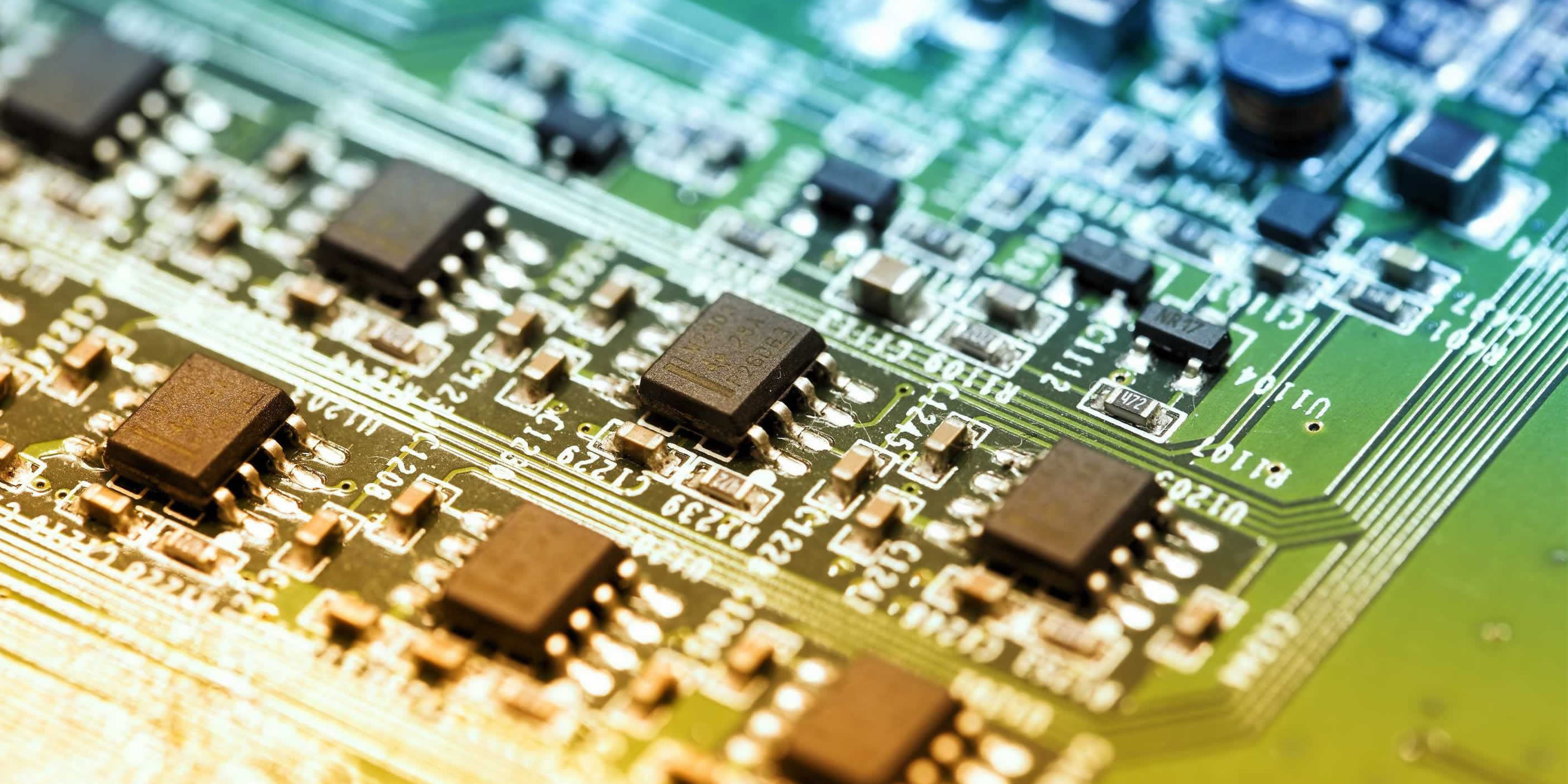

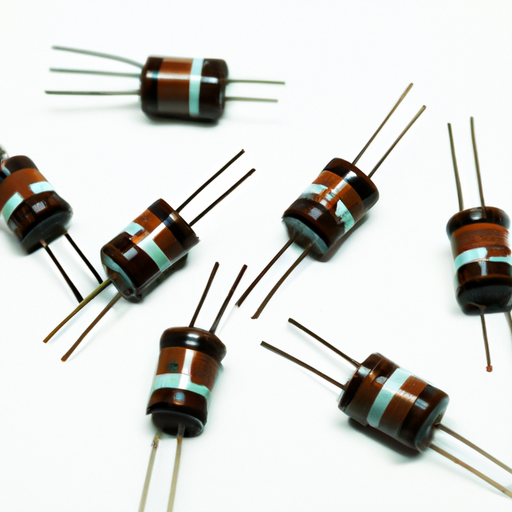

Your supply chain partner

High-quality service dealer in electronic component industry

Professional technical support

We provide professional product technical support for our customers, so as to ensure that they have no worries.

Product quality assurance

To meet customers' expectations and requirements for the physical quality of products with factory control standards superior to domestic and international standards.

Covered industries

We provide professional and ultimate services for more than 100 industries in the upstream and downstream, so that customers can get the most perfect product experience.

Extreme customer service

Strictly control the quality process, ensure the contract delivery cycle, track the quality in time, and deal with quality objections quickly. To provide customers with the most secure and technologically superior pre-,mid-and after-sales services.

Information

Information