Understanding Film Capacitors

I. Introduction

In the world of electronics, capacitors play a crucial role in the functionality of various circuits. Among the different types of capacitors, film capacitors stand out due to their unique properties and applications. This article aims to provide a comprehensive understanding of film capacitors, exploring their structure, operation, advantages, disadvantages, and applications. By the end, you will have a clearer picture of why film capacitors are essential components in modern electronic devices.

II. What is a Film Capacitor?

A. Basic Structure and Components

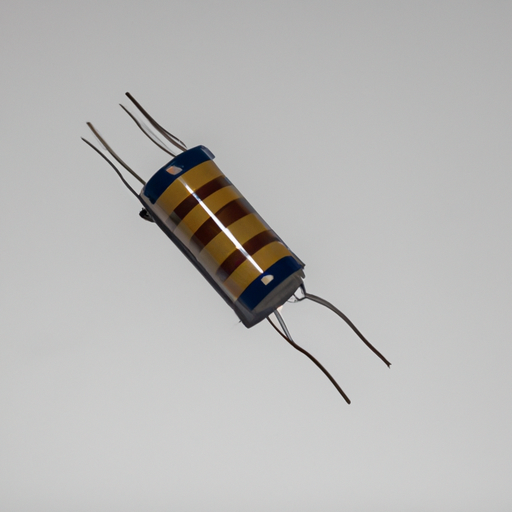

A film capacitor is a type of capacitor that uses a thin plastic film as its dielectric material. The basic structure consists of two conductive plates (electrodes) separated by this dielectric film. The dielectric material is crucial as it determines the capacitor's performance characteristics, including its capacitance, voltage rating, and stability.

1. **Dielectric Material**: The dielectric in film capacitors is typically made from various types of plastic films, which can include polyester (PET), polypropylene (PP), and polycarbonate (PC). Each type of dielectric offers different electrical properties, making them suitable for specific applications.

2. **Electrodes**: The electrodes are usually made of metal, such as aluminum or copper, and are coated onto the dielectric film. The configuration of these electrodes can vary, influencing the capacitor's overall performance.

B. Types of Film Capacitors

Film capacitors can be categorized based on the type of dielectric material used:

1. **Polyester (PET)**: Known for its affordability and decent performance, polyester film capacitors are widely used in general-purpose applications.

2. **Polypropylene (PP)**: These capacitors offer superior performance in terms of low loss and high stability, making them ideal for audio and high-frequency applications.

3. **Polycarbonate (PC)**: While less common today due to their higher cost, polycarbonate capacitors are known for their excellent temperature stability and reliability.

4. **Other Types**: Other film types include polystyrene and polyphenylene sulfide, each with unique properties suited for specific applications.

III. How Film Capacitors Work

A. The Principle of Capacitance

Capacitance is the ability of a capacitor to store electrical energy in an electric field. When a voltage is applied across the electrodes of a film capacitor, an electric field is created across the dielectric material, allowing the capacitor to store charge.

B. Role of the Dielectric Material

The dielectric material plays a vital role in determining the capacitor's performance. It affects the capacitor's capacitance value, voltage rating, and overall stability. A higher dielectric constant allows for greater charge storage in a smaller volume, which is why the choice of dielectric is critical.

C. Charge Storage and Discharge Process

When the capacitor is charged, electrons accumulate on one electrode, creating a negative charge, while the other electrode becomes positively charged. This separation of charge creates an electric field across the dielectric. When the capacitor is connected to a circuit, it can discharge, releasing the stored energy to power the circuit.

IV. Advantages of Film Capacitors

Film capacitors offer several advantages that make them a preferred choice in many applications:

A. Stability and Reliability

Film capacitors are known for their excellent stability over time and under varying environmental conditions. They exhibit minimal changes in capacitance and other electrical properties, ensuring reliable performance.

B. Low Equivalent Series Resistance (ESR)

Film capacitors typically have low ESR, which means they can handle high-frequency signals with minimal energy loss. This characteristic is particularly beneficial in audio and RF applications.

C. High Insulation Resistance

Film capacitors provide high insulation resistance, which reduces the risk of leakage current and enhances safety in electronic circuits.

D. Wide Temperature Range

These capacitors can operate effectively over a wide temperature range, making them suitable for use in diverse environments, from consumer electronics to industrial applications.

E. Non-Polarity

Unlike electrolytic capacitors, film capacitors are non-polarized, allowing them to be connected in either direction in a circuit. This feature simplifies circuit design and reduces the risk of damage due to incorrect connections.

V. Disadvantages of Film Capacitors

Despite their advantages, film capacitors also have some drawbacks:

A. Size and Weight Considerations

Film capacitors tend to be larger and heavier than other types of capacitors, such as ceramic or electrolytic capacitors. This can be a limiting factor in applications where space and weight are critical.

B. Cost Compared to Other Capacitor Types

Film capacitors are generally more expensive than electrolytic and ceramic capacitors. This higher cost can be a consideration in budget-sensitive projects.

C. Limited Capacitance Values

Film capacitors typically have lower capacitance values compared to electrolytic capacitors, which may limit their use in applications requiring high capacitance.

VI. Applications of Film Capacitors

Film capacitors are used in a wide range of applications due to their unique properties:

A. Audio Equipment

In audio applications, film capacitors are favored for their low distortion and high-frequency response, making them ideal for coupling and bypassing applications in amplifiers.

B. Power Electronics

Film capacitors are commonly used in power electronics for energy storage, filtering, and snubber circuits, where their stability and low ESR are advantageous.

C. Signal Processing

In signal processing circuits, film capacitors help maintain signal integrity by minimizing noise and distortion.

D. Timing Circuits

Film capacitors are often used in timing circuits, such as oscillators and timers, due to their predictable capacitance values and stability.

E. Motor Run and Start Applications

In motor applications, film capacitors are used for starting and running motors, providing the necessary phase shift for efficient operation.

VII. Comparison with Other Capacitor Types

When choosing a capacitor, it's essential to understand how film capacitors compare to other types:

A. Electrolytic Capacitors

Electrolytic capacitors offer higher capacitance values but are polarized and less stable over time compared to film capacitors. They are often used in power supply applications.

B. Ceramic Capacitors

Ceramic capacitors are smaller and cheaper but may have lower voltage ratings and stability compared to film capacitors. They are commonly used in high-frequency applications.

C. Tantalum Capacitors

Tantalum capacitors provide high capacitance in a small package but are more expensive and can be less reliable than film capacitors. They are often used in compact electronic devices.

D. Key Differences in Performance and Applications

Each type of capacitor has its strengths and weaknesses, making them suitable for different applications. Film capacitors excel in stability and low ESR, while electrolytic capacitors are preferred for high capacitance needs.

VIII. How to Choose the Right Film Capacitor

When selecting a film capacitor for a specific application, consider the following factors:

A. Factors to Consider

1. **Capacitance Value**: Determine the required capacitance for your application, keeping in mind that film capacitors typically have lower capacitance values.

2. **Voltage Rating**: Ensure the capacitor's voltage rating exceeds the maximum voltage it will encounter in the circuit.

3. **Temperature Rating**: Choose a capacitor with a suitable temperature rating for the operating environment.

4. **Application-Specific Requirements**: Consider any specific requirements related to size, weight, and performance characteristics.

B. Recommendations for Specific Applications

For audio applications, polypropylene film capacitors are often recommended due to their low distortion. In power electronics, polyester film capacitors may be suitable for general-purpose use, while high-performance applications may benefit from polypropylene capacitors.

IX. Conclusion

Film capacitors are essential components in modern electronics, offering stability, reliability, and versatility across various applications. Understanding their structure, operation, advantages, and disadvantages can help you make informed decisions when selecting capacitors for your projects. As technology continues to evolve, film capacitors will likely play an increasingly important role in innovative electronic designs. We encourage you to explore further into capacitor applications and innovations to fully appreciate their impact on the electronics industry.

X. References

For those interested in delving deeper into the world of film capacitors, consider the following resources:

1. "Capacitors: Technology and Applications" by John Smith

2. "Electronic Components: A Complete Reference" by Jane Doe

3. Industry standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

By understanding film capacitors and their applications, you can enhance your knowledge of electronic components and their critical roles in circuit design and functionality.