How to Choose the Function of Spot Capacitor

I. Introduction

A. Definition of Spot Capacitor

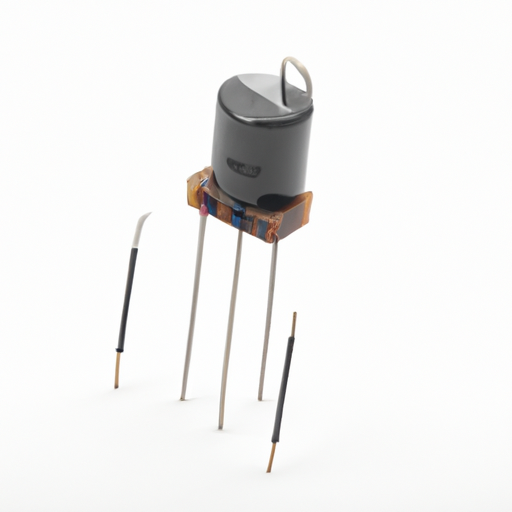

A spot capacitor is a specialized type of capacitor designed for specific applications within electrical systems. Unlike general-purpose capacitors, spot capacitors are tailored to meet the unique demands of particular circuits or devices, ensuring optimal performance and reliability.

B. Importance of Spot Capacitors in Electrical Systems

Spot capacitors play a crucial role in various electrical systems, from industrial machinery to consumer electronics. They help improve power quality, enhance energy efficiency, and ensure the stable operation of electronic devices. By selecting the right spot capacitor, engineers and technicians can significantly impact the performance and longevity of their systems.

C. Purpose of the Article

This article aims to guide readers through the process of choosing the right function of a spot capacitor. By understanding the key factors involved, readers will be better equipped to make informed decisions that align with their specific application needs.

II. Understanding Spot Capacitors

A. What is a Spot Capacitor?

1. Basic Functionality

Spot capacitors store and release electrical energy, acting as a buffer in electrical circuits. They can smooth out voltage fluctuations, provide power during peak demand, and improve overall circuit stability. Their ability to store energy makes them essential in applications requiring quick bursts of power.

2. Types of Spot Capacitors

There are several types of spot capacitors, including ceramic, electrolytic, tantalum, and film capacitors. Each type has its unique characteristics, making them suitable for different applications. For instance, ceramic capacitors are often used in high-frequency applications, while electrolytic capacitors are preferred for power supply filtering due to their high capacitance values.

B. Applications of Spot Capacitors

1. Power Factor Correction

In industrial settings, spot capacitors are commonly used for power factor correction. By compensating for inductive loads, they help improve the efficiency of electrical systems, reducing energy costs and minimizing the risk of equipment damage.

2. Voltage Regulation

Spot capacitors also play a vital role in voltage regulation. They help maintain a stable voltage level in power supplies, ensuring that electronic devices operate within their specified voltage range. This is particularly important in sensitive applications, such as medical equipment and telecommunications.

3. Energy Storage

In renewable energy systems, spot capacitors are used for energy storage. They can store excess energy generated by solar panels or wind turbines and release it when needed, helping to balance supply and demand.

III. Key Factors to Consider When Choosing a Spot Capacitor

A. Electrical Specifications

1. Voltage Rating

The voltage rating of a spot capacitor indicates the maximum voltage it can handle without failure. It is crucial to select a capacitor with a voltage rating that exceeds the maximum voltage expected in the application to ensure reliability and safety.

2. Capacitance Value

The capacitance value determines how much electrical energy the capacitor can store. It is essential to choose a capacitance value that meets the specific requirements of the application, as too low a value may lead to insufficient energy storage, while too high a value can result in unnecessary costs and space usage.

3. Ripple Current Rating

The ripple current rating indicates the maximum AC current the capacitor can handle without overheating. This is particularly important in applications with fluctuating currents, such as power supplies and motor drives.

B. Environmental Conditions

1. Temperature Range

Spot capacitors must be able to operate within the temperature range of their intended environment. High temperatures can lead to reduced lifespan and performance, while low temperatures can affect capacitance values.

2. Humidity and Moisture Resistance

In humid or wet environments, moisture can compromise the performance of spot capacitors. Selecting capacitors with appropriate moisture resistance ratings is essential for ensuring reliability in such conditions.

3. Vibration and Shock Resistance

For applications in industrial settings or mobile devices, capacitors must withstand vibrations and shocks. Choosing capacitors with adequate mechanical stability is crucial to prevent failure in these environments.

C. Physical Size and Form Factor

1. Space Constraints

The physical size of the capacitor is an important consideration, especially in compact electronic devices. Engineers must ensure that the selected capacitor fits within the available space without compromising performance.

2. Mounting Options

Different applications may require different mounting options, such as surface mount or through-hole. Understanding the mounting requirements is essential for proper integration into the circuit.

IV. Evaluating Performance Characteristics

A. Equivalent Series Resistance (ESR)

ESR is a critical parameter that affects the efficiency of a capacitor. A lower ESR indicates better performance, particularly in high-frequency applications. When selecting a spot capacitor, it is essential to consider its ESR to ensure optimal performance.

B. Lifetime and Reliability

The expected lifetime of a capacitor is influenced by factors such as temperature, voltage, and ripple current. Choosing capacitors with a longer lifespan can reduce maintenance costs and improve system reliability.

C. Self-Discharge Rate

The self-discharge rate indicates how quickly a capacitor loses its stored charge when not in use. A lower self-discharge rate is preferable for applications requiring long-term energy storage.

D. Frequency Response

The frequency response of a capacitor determines its effectiveness in filtering out unwanted signals. Understanding the frequency characteristics of the capacitor is essential for applications involving signal processing.

V. Application-Specific Considerations

A. Industrial Applications

1. Motor Drives

In motor drive applications, spot capacitors are used for energy storage and power factor correction. Selecting capacitors with high ripple current ratings and appropriate capacitance values is crucial for optimal performance.

2. Power Supplies

Spot capacitors in power supplies help smooth out voltage fluctuations and improve efficiency. Engineers must consider the voltage rating, capacitance value, and ESR when selecting capacitors for these applications.

B. Consumer Electronics

1. Audio Equipment

In audio equipment, spot capacitors are used for filtering and coupling signals. Choosing capacitors with low ESR and appropriate capacitance values is essential for maintaining audio quality.

2. Home Appliances

Home appliances often require capacitors for motor starting and power factor correction. Selecting the right capacitors can enhance performance and energy efficiency.

C. Renewable Energy Systems

1. Solar Inverters

In solar inverters, spot capacitors are used for energy storage and voltage regulation. Engineers must consider the environmental conditions and electrical specifications when selecting capacitors for these applications.

2. Wind Turbines

Spot capacitors in wind turbines help manage energy storage and improve power quality. Choosing capacitors with high reliability and performance characteristics is essential for ensuring the longevity of the system.

VI. Cost Considerations

A. Budget Constraints

When selecting spot capacitors, budget constraints are often a significant factor. Engineers must balance performance requirements with cost to ensure the project remains within budget.

B. Cost vs. Performance Trade-offs

In some cases, higher-performing capacitors may come at a premium price. It is essential to evaluate the cost versus performance trade-offs to make informed decisions that align with project goals.

C. Long-term Value and Return on Investment

Investing in high-quality spot capacitors can lead to long-term value and improved system performance. Evaluating the return on investment is crucial for making informed purchasing decisions.

VII. Conclusion

A. Recap of Key Points

Choosing the right function of a spot capacitor involves understanding its electrical specifications, environmental conditions, physical size, performance characteristics, and application-specific needs. By considering these factors, engineers can make informed decisions that enhance system performance and reliability.

B. Importance of Informed Decision-Making

Informed decision-making is essential when selecting spot capacitors. Understanding the unique requirements of each application can lead to better performance and reduced costs.

C. Encouragement to Consult with Experts for Specific Applications

For complex applications or when in doubt, consulting with experts can provide valuable insights and guidance. Engaging with manufacturers and industry professionals can help ensure the right capacitor is chosen for the specific needs of the project.

VIII. References

A. Suggested Reading

- "Capacitors: Technology and Applications" by John Smith

- "Power Factor Correction: A Practical Guide" by Jane Doe

B. Industry Standards and Guidelines

- IEC 61071: Standard for capacitors for power electronics

- IEEE 18: Standard for the measurement of capacitance and dissipation factor

C. Manufacturer Resources

- Manufacturer datasheets and application notes

- Technical support from capacitor manufacturers

By following this comprehensive guide, readers can navigate the complexities of selecting spot capacitors, ensuring they choose the right components for their specific applications.