CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

What are the product features of the capacitor factory?

What are the Product Features of a Capacitor Factory?

I. Introduction

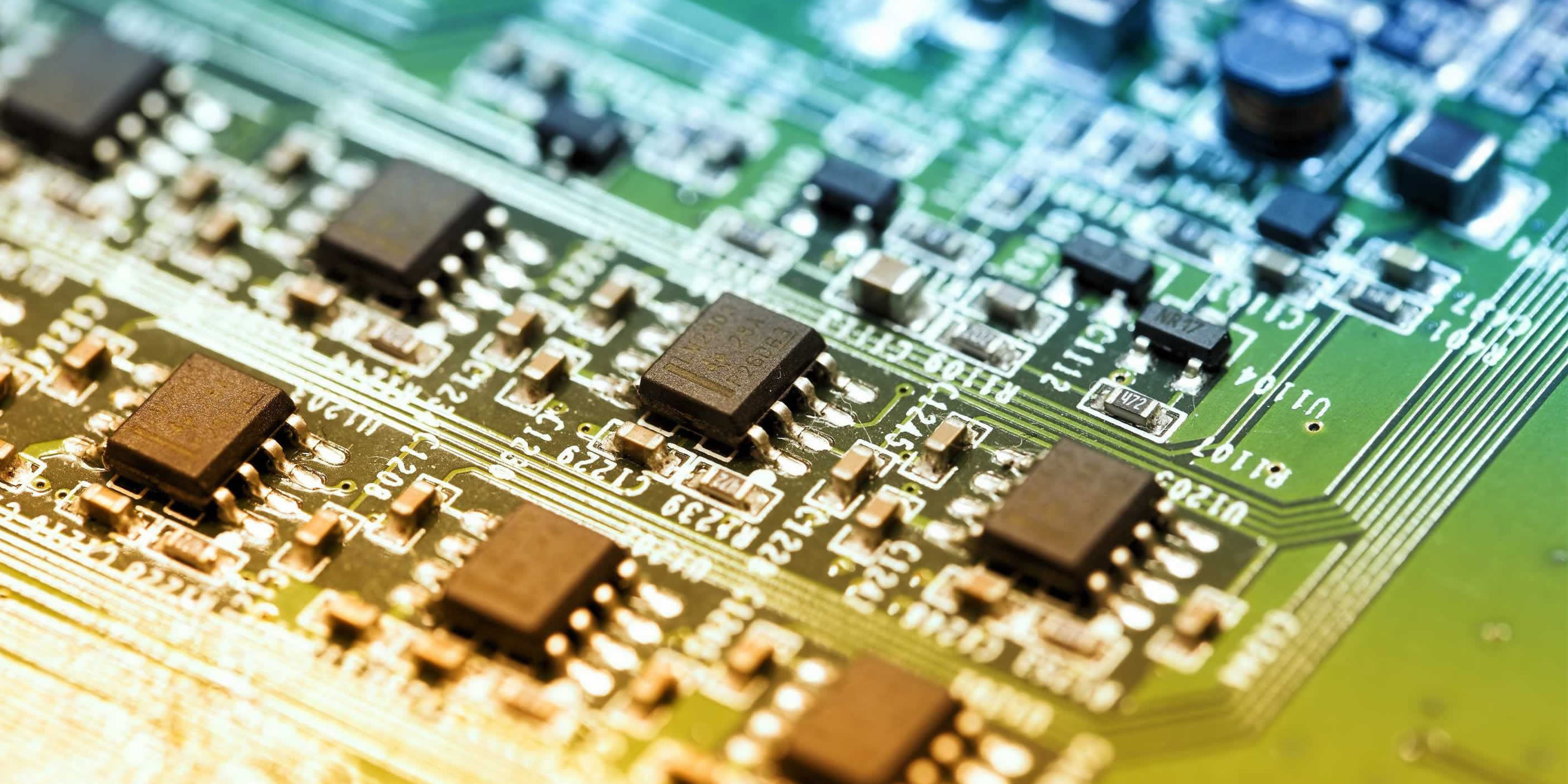

Capacitors are essential components in electronic devices, serving as energy storage units that can release energy quickly when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to enabling signal processing in communication devices. The capacitor manufacturing industry has evolved significantly over the years, driven by technological advancements and the increasing demand for electronic devices. This blog post will explore the product features of a capacitor factory, delving into the types of capacitors produced, manufacturing processes, technological innovations, environmental considerations, customization options, and market trends.

II. Types of Capacitors Produced

Capacitor factories produce a variety of capacitor types, each with unique characteristics and applications.

A. Ceramic Capacitors

Ceramic capacitors are widely used due to their small size, low cost, and reliability. They are made from ceramic materials that exhibit dielectric properties. These capacitors are ideal for high-frequency applications, such as RF circuits and decoupling in power supplies. Their stability and low loss make them suitable for various consumer electronics, including smartphones and computers.

B. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values and are typically used in power supply applications. They consist of an electrolyte and a metal oxide layer, which allows them to store a significant amount of charge. Common applications include filtering and energy storage in power supplies, audio equipment, and industrial machinery.

C. Film Capacitors

Film capacitors are made from thin plastic films as the dielectric material. They are known for their stability, low loss, and excellent performance in high-frequency applications. These capacitors are often used in audio equipment, power electronics, and automotive applications due to their reliability and long lifespan.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are made from tantalum metal and are often used in applications where space is limited, such as in mobile devices and medical equipment. Their ability to operate at high temperatures and voltages makes them suitable for demanding environments.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They can store large amounts of energy and release it quickly, making them ideal for applications requiring rapid charge and discharge cycles. Common uses include energy recovery systems, backup power supplies, and electric vehicles.

III. Manufacturing Processes

The manufacturing of capacitors involves several critical processes that ensure the quality and performance of the final product.

A. Raw Material Selection

The selection of raw materials is crucial in capacitor manufacturing. Factories implement stringent quality control measures to ensure that the materials used meet industry standards. Additionally, many manufacturers are now sourcing sustainable materials to minimize their environmental impact.

B. Production Techniques

The production of capacitors involves several key techniques:

1. **Dielectric Layer Formation**: The dielectric layer is a critical component of capacitors, and its formation requires precision. Various methods, such as sputtering and chemical vapor deposition, are used to create thin dielectric layers that enhance performance.

2. **Electrode Preparation**: The electrodes are prepared using materials that provide excellent conductivity. This process often involves etching and coating techniques to ensure optimal performance.

3. **Assembly Processes**: The assembly of capacitors involves integrating the dielectric and electrodes into a compact form. Automated assembly lines are commonly used to enhance efficiency and reduce production costs.

C. Quality Assurance

Quality assurance is a vital aspect of capacitor manufacturing. Factories employ various testing methods, including electrical testing, thermal cycling, and life testing, to ensure that the capacitors meet performance specifications. Compliance with industry standards, such as ISO and RoHS, is also a critical focus.

IV. Technological Innovations

The capacitor manufacturing industry is continuously evolving, with several technological innovations shaping the future of capacitor production.

A. Automation in Manufacturing

Automation has revolutionized the manufacturing process, with robotics and AI integration enhancing efficiency and precision. Automated systems can perform repetitive tasks with high accuracy, reducing the risk of human error and increasing production rates.

B. Advanced Materials

The development of new dielectric materials has significantly impacted capacitor performance and efficiency. Researchers are exploring materials that offer higher capacitance, lower losses, and improved thermal stability, which can lead to more compact and efficient capacitors.

C. Miniaturization Trends

As electronic devices become smaller and more powerful, the demand for miniaturized capacitors has increased. Manufacturers are focusing on producing smaller form factors without compromising performance, allowing for innovative designs in consumer electronics and other applications.

V. Environmental Considerations

As the world becomes more environmentally conscious, capacitor factories are adopting sustainable manufacturing practices.

A. Sustainable Manufacturing Practices

Many manufacturers are implementing waste reduction strategies, such as recycling scrap materials and optimizing production processes to minimize waste. Energy-efficient processes are also being adopted to reduce the carbon footprint of manufacturing operations.

B. Recycling and End-of-Life Management

Capacitor factories are increasingly focusing on recycling programs to manage the end-of-life of capacitors. These programs aim to recover valuable materials and reduce environmental impact. Environmental impact assessments are conducted to ensure compliance with regulations and to promote sustainable practices.

VI. Customization and Customer Support

Capacitor factories often provide tailored solutions to meet the specific needs of their clients.

A. Tailored Solutions for Clients

Manufacturers offer custom capacitor designs to accommodate unique specifications and applications. Prototyping and testing services are also available to ensure that the capacitors meet the required performance standards before mass production.

B. Technical Support and Consultation

Expertise in capacitor selection is crucial for clients, and many manufacturers provide technical support and consultation services. This assistance helps clients choose the right capacitors for their applications and ensures optimal performance.

VII. Market Trends and Future Outlook

The capacitor market is experiencing significant growth, driven by the increasing demand for electronic devices.

A. Growing Demand for Capacitors

The electronics industry is a major driver of capacitor demand, with emerging markets and applications contributing to this growth. As technology advances, the need for reliable and efficient capacitors will continue to rise.

B. Future Innovations

Research and development efforts are focused on several key areas, including the development of new materials, improved manufacturing processes, and enhanced performance characteristics. Predictions for the capacitor market indicate continued growth and innovation, with manufacturers striving to meet the evolving needs of the electronics industry.

VIII. Conclusion

In summary, capacitor factories play a vital role in the production of essential components for modern electronics. From the diverse types of capacitors produced to the advanced manufacturing processes and technological innovations, these factories are at the forefront of the electronics industry. As the demand for capacitors continues to grow, manufacturers are committed to sustainability, customization, and customer support, ensuring that they meet the needs of their clients while contributing to technological advancement. Capacitors remain a cornerstone of modern electronics, and their importance will only increase in the future.

2024-12-12

0

What are the product features of capacitor discharge?

What are the Product Features of Capacitor Discharge?

I. Introduction

Capacitor discharge is a fundamental concept in electronics that plays a crucial role in various applications, from consumer electronics to industrial machinery. At its core, capacitor discharge refers to the process by which a capacitor releases the electrical energy it has stored. Understanding this process is essential for engineers, technicians, and anyone involved in the design and application of electronic systems. This article will explore the basic principles of capacitor discharge, its product features, applications, advantages, challenges, and future trends in capacitor technology.

II. Basic Principles of Capacitor Discharge

A. Explanation of Capacitors

1. **Structure and Function**: A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

2. **Types of Capacitors**: There are several types of capacitors, including ceramic, electrolytic, tantalum, and film capacitors. Each type has its unique characteristics, making them suitable for different applications. For instance, electrolytic capacitors are often used for high-capacity applications, while ceramic capacitors are favored for high-frequency applications.

B. The Discharge Process

1. **How Capacitors Store Energy**: Capacitors store energy in the form of an electric field created between their plates. The amount of energy stored is proportional to the capacitance and the square of the voltage across the plates, as described by the formula:

\[

E = \frac{1}{2} C V^2

\]

where \(E\) is energy, \(C\) is capacitance, and \(V\) is voltage.

2. **Mechanism of Discharge**: When a capacitor is connected to a load, it begins to discharge, releasing the stored energy. The discharge process can be rapid or slow, depending on the load's resistance and the capacitor's characteristics.

C. Key Parameters

1. **Voltage**: The voltage rating of a capacitor indicates the maximum voltage it can handle without breaking down. Exceeding this voltage can lead to failure or even explosion.

2. **Capacitance**: Measured in farads (F), capacitance indicates the amount of charge a capacitor can store per volt. Higher capacitance values allow for more energy storage.

3. **Time Constant**: The time constant (\(\tau\)) is a measure of how quickly a capacitor charges or discharges. It is calculated as the product of resistance (R) and capacitance (C):

\[

\tau = R \times C

\]

A larger time constant indicates a slower discharge rate.

III. Product Features of Capacitor Discharge

A. Energy Delivery

1. **High Energy Output**: Capacitors can deliver a significant amount of energy in a short time, making them ideal for applications requiring bursts of power.

2. **Rapid Discharge Capabilities**: The ability to discharge quickly is a critical feature, especially in applications like automotive airbag systems, where rapid deployment is essential for safety.

B. Versatility

1. **Applications in Various Industries**: Capacitor discharge technology is utilized across multiple sectors, including automotive, consumer electronics, industrial machinery, and medical devices.

2. **Compatibility with Different Systems**: Capacitors can be integrated into various electronic systems, enhancing their functionality and performance.

C. Safety Features

1. **Overvoltage Protection**: Many capacitors are designed with built-in safety features to prevent damage from voltage spikes, ensuring reliable operation.

2. **Short-Circuit Protection**: Capacitors can also include mechanisms to protect against short circuits, which can lead to catastrophic failures.

D. Efficiency

1. **Low Energy Loss**: Capacitors are known for their efficiency, with minimal energy loss during charge and discharge cycles.

2. **High Charge/Discharge Cycles**: Capacitors can endure numerous charge and discharge cycles without significant degradation, making them a reliable choice for long-term applications.

E. Size and Form Factor

1. **Compact Designs**: Modern capacitors are available in compact sizes, allowing for integration into space-constrained applications.

2. **Customizable Options**: Manufacturers offer customizable capacitor solutions to meet specific application requirements, including size, capacitance, and voltage ratings.

IV. Applications of Capacitor Discharge

A. Automotive Industry

1. **Use in Airbag Systems**: Capacitors are critical in automotive airbag systems, providing the rapid energy discharge needed to inflate airbags in milliseconds during a collision.

2. **Powering Electric Motors**: Capacitor discharge is also used to provide the initial power surge required to start electric motors in hybrid and electric vehicles.

B. Consumer Electronics

1. **Flash Photography**: Capacitors are used in camera flash units, storing energy and releasing it quickly to produce a bright flash of light.

2. **Power Supply for Portable Devices**: Capacitors help stabilize power supplies in portable electronics, ensuring consistent performance.

C. Industrial Applications

1. **Welding Equipment**: Capacitor discharge is employed in resistance welding, where capacitors provide the necessary energy for the welding process.

2. **Pulse Power Applications**: Capacitors are used in pulse power systems for applications like particle accelerators and laser systems, where high-energy pulses are required.

D. Medical Devices

1. **Defibrillators**: Capacitors are essential in defibrillators, storing energy and delivering it in a controlled manner to restore normal heart rhythm.

2. **Imaging Equipment**: Capacitors are used in medical imaging devices, providing the necessary power for rapid image capture.

V. Advantages of Capacitor Discharge

A. Quick Response Time

Capacitors can respond almost instantaneously to changes in voltage, making them ideal for applications requiring rapid energy delivery.

B. High Power Density

Capacitors can deliver a high amount of power relative to their size, making them suitable for compact electronic devices.

C. Reliability and Longevity

With minimal wear and tear, capacitors can last for many years, providing reliable performance in various applications.

D. Cost-Effectiveness

While the initial cost of capacitors may vary, their longevity and efficiency often make them a cost-effective solution in the long run.

VI. Challenges and Considerations

A. Limitations of Capacitor Discharge

1. **Energy Density Compared to Batteries**: While capacitors can discharge energy quickly, they typically have lower energy density than batteries, making them less suitable for long-term energy storage.

2. **Temperature Sensitivity**: Capacitors can be sensitive to temperature changes, which can affect their performance and lifespan.

B. Maintenance and Lifecycle

1. **Regular Testing**: To ensure optimal performance, capacitors should be regularly tested, especially in critical applications.

2. **Replacement Considerations**: Over time, capacitors may degrade and require replacement, necessitating careful planning in system design.

VII. Conclusion

In summary, capacitor discharge is a vital aspect of modern electronics, offering numerous product features that enhance performance across various applications. From high energy output and rapid discharge capabilities to safety features and efficiency, capacitors play a crucial role in many industries. As technology continues to evolve, the importance of capacitor discharge will only grow, paving the way for innovative applications and advancements in electronic systems. Understanding these features and their implications is essential for anyone involved in the design and application of electronic devices, ensuring that they can leverage the full potential of capacitor technology in their projects.

2024-12-11

0

What are the development trends in the capacitor voltage industry?

Development Trends in the Capacitor Voltage Industry

I. Introduction

Capacitors are fundamental components in electrical systems, serving as energy storage devices that can release energy quickly when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to enabling high-frequency signal processing in electronic circuits. The capacitor voltage industry, which encompasses the design, manufacturing, and application of capacitors, is significant in modern technology, influencing everything from consumer electronics to renewable energy systems. This blog post explores the development trends in the capacitor voltage industry, highlighting historical context, current market dynamics, technological advancements, environmental considerations, challenges, and future outlook.

II. Historical Context

The history of capacitors dates back to the 18th century with the invention of the Leyden jar, one of the first devices capable of storing electrical energy. Over the years, capacitor technology has evolved significantly, with key milestones including the development of electrolytic capacitors in the early 20th century and the introduction of ceramic and film capacitors in the mid-20th century. These advancements have led to a transition from traditional designs, which were often bulky and limited in performance, to modern capacitors that are smaller, more efficient, and capable of handling higher voltages and frequencies.

III. Current Market Landscape

A. Overview of the Global Capacitor Market

The global capacitor market has experienced substantial growth in recent years, driven by the increasing demand for electronic devices and the expansion of renewable energy systems. According to market research, the capacitor market is projected to reach approximately $30 billion by 2025, with a compound annual growth rate (CAGR) of around 5%. Key players in the industry include companies like Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation, which collectively hold significant market shares.

B. Types of Capacitors and Their Applications

Capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Widely used in high-frequency applications due to their stability and low losses.

2. **Electrolytic Capacitors**: Commonly found in power supply circuits, known for their high capacitance values.

3. **Film Capacitors**: Valued for their reliability and performance in audio and power applications.

4. **Tantalum Capacitors**: Used in compact electronic devices, offering high capacitance in a small package.

C. Emerging Markets and Demand Drivers

Emerging markets, particularly in Asia-Pacific, are driving demand for capacitors. The rapid growth of consumer electronics, automotive electronics, and renewable energy sectors in countries like China and India is contributing to this trend. Additionally, the increasing adoption of electric vehicles (EVs) and energy-efficient technologies is expected to further boost the capacitor voltage industry.

IV. Technological Advancements

A. Innovations in Capacitor Materials

Recent innovations in capacitor materials have significantly enhanced performance. The development of high-k dielectrics allows for greater capacitance in smaller sizes, while nanotechnology is being utilized to create capacitors with improved energy density and efficiency. These advancements enable capacitors to meet the demands of modern electronic devices, which require compact and high-performance components.

B. Miniaturization and Integration

The trend towards miniaturization is evident in the capacitor industry, with manufacturers focusing on producing smaller, more efficient capacitors. This miniaturization is often accompanied by integration with other electronic components, leading to the development of multi-functional devices that can perform multiple tasks within a single package. This trend is particularly relevant in the context of smartphones, wearables, and other compact electronic devices.

C. Smart Capacitors and IoT Integration

The rise of the Internet of Things (IoT) has opened new avenues for capacitor applications. Smart capacitors are being developed to enhance the efficiency of smart grids and renewable energy systems. These capacitors can monitor and adjust their performance in real-time, contributing to energy savings and improved grid stability. Additionally, capacitors are increasingly being integrated into consumer electronics and smart devices, enabling features such as energy harvesting and power management.

V. Environmental and Regulatory Trends

A. Impact of Environmental Regulations on Capacitor Manufacturing

Environmental regulations are shaping the capacitor industry, with directives such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) pushing manufacturers to adopt sustainable practices. These regulations aim to reduce the environmental impact of electronic waste and promote the use of eco-friendly materials in capacitor production.

B. Trends Towards Energy Efficiency and Reduced Carbon Footprint

As global awareness of climate change grows, there is a strong push for energy-efficient technologies across all industries. Capacitors play a vital role in this transition, as they are essential for energy storage and management in renewable energy systems. Manufacturers are increasingly focusing on developing capacitors that not only meet performance standards but also contribute to a reduced carbon footprint.

C. Corporate Social Responsibility in the Capacitor Industry

Corporate social responsibility (CSR) is becoming a key consideration for companies in the capacitor industry. Many manufacturers are adopting sustainable practices, such as using recycled materials and implementing energy-efficient production processes. This shift not only helps meet regulatory requirements but also appeals to environmentally conscious consumers.

VI. Challenges Facing the Industry

A. Supply Chain Disruptions and Material Shortages

The capacitor industry faces challenges related to supply chain disruptions and material shortages, particularly in the wake of the COVID-19 pandemic. These disruptions have affected the availability of key raw materials, leading to increased production costs and delays in manufacturing.

B. Competition from Alternative Energy Storage Solutions

As the demand for energy storage solutions grows, capacitors face competition from alternative technologies such as batteries and supercapacitors. While capacitors offer advantages in terms of charge and discharge rates, they may not always provide the energy density required for certain applications, prompting manufacturers to innovate and improve their products.

C. Balancing Performance, Cost, and Sustainability

Manufacturers must navigate the delicate balance between performance, cost, and sustainability. While there is a growing demand for high-performance capacitors, the pressure to keep costs low and adhere to environmental regulations complicates the development process. Companies that can successfully balance these factors will be better positioned to thrive in the competitive landscape.

VII. Future Outlook

A. Predictions for the Capacitor Voltage Industry Over the Next Decade

Looking ahead, the capacitor voltage industry is expected to continue its growth trajectory, driven by advancements in technology and increasing demand for electronic devices. The integration of capacitors into emerging technologies such as electric vehicles, renewable energy systems, and smart devices will further fuel this growth.

B. Potential Areas for Research and Development

Future research and development efforts are likely to focus on enhancing capacitor performance, exploring new materials, and improving manufacturing processes. Areas such as solid-state capacitors, advanced dielectric materials, and energy-efficient designs will be critical for meeting the evolving needs of the market.

C. The Role of Capacitors in Future Technological Advancements

Capacitors will play a pivotal role in supporting future technological advancements, particularly in the fields of renewable energy, electric mobility, and smart technologies. As the world moves towards a more sustainable and interconnected future, capacitors will remain essential components in driving innovation and efficiency.

VIII. Conclusion

In conclusion, the capacitor voltage industry is undergoing significant transformation, shaped by historical developments, current market dynamics, technological advancements, and environmental considerations. As the demand for high-performance, energy-efficient capacitors continues to rise, manufacturers must adapt to the challenges and opportunities presented by this evolving landscape. The importance of capacitors in supporting future innovations cannot be overstated, as they remain integral to the advancement of modern technology. As we look to the future, the evolution of the capacitor voltage industry will undoubtedly play a crucial role in shaping the world of electronics and energy management.

2024-12-10

0