What is the Energy Storage Production Process of Mainstream Capacitors?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy quickly when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to enabling rapid discharge in flash photography. As the demand for efficient energy storage solutions grows, understanding the production processes of mainstream capacitors becomes increasingly important. This article delves into the types of capacitors, their energy storage principles, raw materials, production processes, innovations, challenges, and future trends.

II. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications.

A. Electrolytic Capacitors

Electrolytic capacitors are polarized devices that offer high capacitance values in a compact size. They are commonly used in power supply circuits, audio equipment, and energy storage applications. Their construction typically involves an aluminum or tantalum anode, a dielectric oxide layer, and a liquid or solid electrolyte.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and are known for their stability and reliability. They are widely used in high-frequency applications, such as RF circuits and decoupling applications. Their dielectric material is made from ceramic compounds, which provide excellent temperature stability.

C. Film Capacitors

Film capacitors utilize thin plastic films as their dielectric material. They are known for their low loss, high insulation resistance, and long lifespan. Common applications include power electronics, audio equipment, and motor run applications.

D. Supercapacitors

Supercapacitors, or ultracapacitors, bridge the gap between traditional capacitors and batteries. They offer high energy density and rapid charge/discharge capabilities, making them ideal for applications like regenerative braking in electric vehicles and energy storage in renewable energy systems.

III. Basic Principles of Energy Storage in Capacitors

A. Charge Storage Mechanism

Capacitors store energy in the form of an electric field created between two conductive plates separated by a dielectric material. When a voltage is applied, positive and negative charges accumulate on the plates, creating an electric field that stores energy.

B. Dielectric Materials and Their Role

The dielectric material is crucial in determining a capacitor's performance. It affects the capacitance value, voltage rating, and temperature stability. Common dielectric materials include ceramic, plastic films, and electrolytes, each offering distinct advantages.

C. Capacitance and Its Significance

Capacitance, measured in farads, quantifies a capacitor's ability to store charge. It is influenced by the surface area of the conductive plates, the distance between them, and the properties of the dielectric material. Higher capacitance values allow for greater energy storage, making it a critical factor in capacitor design.

IV. Raw Materials Used in Capacitor Production

The production of capacitors involves various raw materials, each contributing to the final product's performance.

A. Conductive Materials

1. **Metals**: Aluminum and tantalum are commonly used for electrodes due to their excellent conductivity and ability to form a stable oxide layer.

2. **Conductive Polymers**: These materials are increasingly used in applications requiring flexibility and lightweight components.

B. Dielectric Materials

1. **Types of Dielectrics**: Ceramic materials, plastic films, and electrolytes are the primary dielectrics used in capacitors. Each type offers unique properties that cater to specific applications.

C. Other Materials

1. **Packaging Materials**: The encapsulation of capacitors is essential for protection against environmental factors.

2. **Adhesives and Coatings**: These materials ensure the integrity of the capacitor structure and enhance performance.

V. The Production Process of Capacitors

The production of capacitors involves several key steps, from design to quality assurance.

A. Design and Engineering

The process begins with design and engineering, where specifications and requirements are established. Prototyping and testing are conducted to ensure the design meets performance criteria.

B. Material Preparation

Sourcing high-quality raw materials is critical. Quality control measures are implemented to ensure that materials meet industry standards. Raw materials are then processed to prepare them for manufacturing.

C. Manufacturing Steps

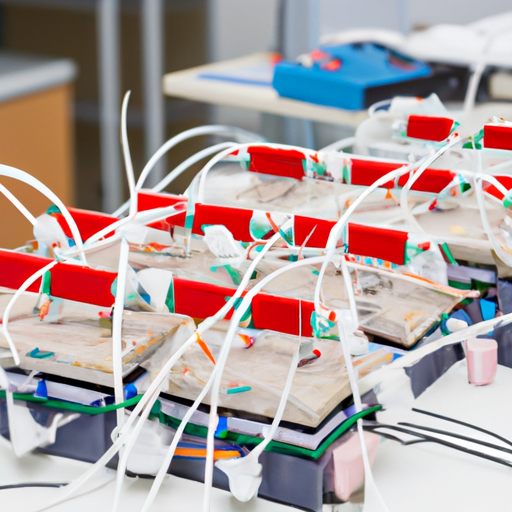

1. **Electrode Fabrication**: This involves metal deposition techniques, such as sputtering or evaporation, followed by etching and patterning to create the desired electrode shapes.

2. **Dielectric Layer Application**: The dielectric material is applied using coating methods, such as spray coating or roll-to-roll processing. Curing processes are then employed to solidify the dielectric layer.

3. **Assembly**: The capacitor is assembled by stacking layers of electrodes and dielectrics, followed by encapsulation to protect the internal components.

D. Quality Assurance

Quality assurance is a critical step in the production process. Capacitors undergo rigorous testing for performance and reliability, ensuring compliance with industry standards. This includes electrical testing, thermal cycling, and life testing.

VI. Innovations in Capacitor Production

The capacitor industry is witnessing significant innovations that enhance performance and sustainability.

A. Advances in Materials Science

Research in materials science is leading to the development of new dielectric materials that offer higher capacitance and improved thermal stability. These advancements enable the production of smaller, more efficient capacitors.

B. Automation and Smart Manufacturing

Automation in manufacturing processes increases efficiency and reduces production costs. Smart manufacturing technologies, such as IoT and AI, are being integrated into production lines to optimize operations and improve quality control.

C. Environmental Considerations and Sustainability

As environmental concerns grow, manufacturers are focusing on sustainable practices. This includes using eco-friendly materials, reducing waste, and implementing energy-efficient production processes.

VII. Challenges in Capacitor Production

Despite advancements, the capacitor industry faces several challenges.

A. Material Shortages and Supply Chain Issues

Global supply chain disruptions can lead to material shortages, impacting production timelines and costs. Manufacturers must develop strategies to mitigate these risks.

B. Cost Management

Balancing production costs while maintaining quality is a constant challenge. Manufacturers are exploring ways to optimize processes and reduce material costs without compromising performance.

C. Meeting Increasing Demand for Energy Storage Solutions

The rising demand for energy storage solutions, driven by the growth of renewable energy and electric vehicles, places pressure on manufacturers to scale production while maintaining quality.

VIII. Future Trends in Capacitor Technology

The future of capacitor technology is promising, with several trends emerging.

A. Emerging Capacitor Technologies

New capacitor technologies, such as solid-state capacitors and hybrid capacitors, are being developed to meet the demands of modern applications. These technologies offer improved performance and safety.

B. Integration with Renewable Energy Systems

Capacitors are increasingly being integrated into renewable energy systems, providing essential energy storage and management capabilities. This trend is expected to grow as the world shifts towards sustainable energy solutions.

C. Potential for Miniaturization and Enhanced Performance

As electronic devices become smaller and more powerful, the demand for miniaturized capacitors with enhanced performance will continue to rise. Innovations in materials and manufacturing processes will play a crucial role in achieving this goal.

IX. Conclusion

Capacitors are vital components in energy storage and electronic circuits, and understanding their production processes is essential for advancing technology. From the various types of capacitors to the intricate manufacturing steps, each aspect contributes to their performance and reliability. As the industry faces challenges and embraces innovations, the future of capacitor technology holds great promise for enhancing energy storage solutions. With ongoing research and development, capacitors will continue to play a pivotal role in the transition to a more sustainable energy landscape.

What are the Product Characteristics of Energy Storage Capacitors?

I. Introduction

A. Definition of Energy Storage Capacitors

Energy storage capacitors are electronic components that store electrical energy in an electric field, allowing for rapid charge and discharge cycles. Unlike traditional batteries, which rely on chemical reactions to store energy, capacitors can deliver energy almost instantaneously, making them essential in various applications where quick bursts of power are required.

B. Importance of Energy Storage in Modern Applications

As the demand for energy-efficient solutions grows, energy storage capacitors have become increasingly vital in modern technology. They play a crucial role in renewable energy systems, electric vehicles, and consumer electronics, helping to stabilize power supply, improve efficiency, and enhance performance. Understanding the characteristics of these capacitors is essential for engineers and designers to select the right components for their applications.

C. Overview of the Article

This article will explore the different types of energy storage capacitors, their key product characteristics, performance metrics, applications, and future trends. By the end, readers will have a comprehensive understanding of energy storage capacitors and their significance in today's technological landscape.

II. Types of Energy Storage Capacitors

A. Electrolytic Capacitors

1. Characteristics

Electrolytic capacitors are polarized components that offer high capacitance values in a relatively small package. They typically have a capacitance range from microfarads (µF) to millifarads (mF) and are known for their high energy density.

2. Applications

These capacitors are widely used in power supply circuits, audio equipment, and energy storage applications due to their ability to handle large amounts of energy.

B. Ceramic Capacitors

1. Characteristics

Ceramic capacitors are non-polarized and are known for their stability and reliability. They have lower capacitance values compared to electrolytic capacitors but offer excellent frequency characteristics and low ESR.

2. Applications

Commonly used in high-frequency applications, such as RF circuits and decoupling applications, ceramic capacitors are favored for their small size and robustness.

C. Film Capacitors

1. Characteristics

Film capacitors use a thin plastic film as the dielectric material. They are known for their low ESR, high voltage ratings, and excellent thermal stability.

2. Applications

These capacitors are often used in audio equipment, power electronics, and applications requiring high precision and stability.

D. Supercapacitors

1. Characteristics

Supercapacitors, also known as ultracapacitors, bridge the gap between traditional capacitors and batteries. They offer high capacitance values and can store significant amounts of energy while allowing for rapid charge and discharge cycles.

2. Applications

Supercapacitors are increasingly used in applications such as energy harvesting, backup power supplies, and electric vehicles due to their ability to deliver high power quickly.

E. Comparison of Different Types

Each type of energy storage capacitor has its unique characteristics and applications. Electrolytic capacitors are best for high energy storage, ceramic capacitors excel in high-frequency applications, film capacitors offer stability, and supercapacitors provide rapid energy delivery. Understanding these differences is crucial for selecting the right capacitor for specific applications.

III. Key Product Characteristics

A. Capacitance Value

1. Definition and Importance

Capacitance is the ability of a capacitor to store electrical charge, measured in farads (F). The capacitance value determines how much energy a capacitor can store and is a critical factor in its performance.

2. Measurement Units

Capacitance is typically measured in microfarads (µF), nanofarads (nF), or picofarads (pF), depending on the application.

B. Voltage Rating

1. Definition and Importance

The voltage rating indicates the maximum voltage a capacitor can handle without breaking down. Exceeding this rating can lead to capacitor failure, making it a vital characteristic to consider.

2. Impact on Performance

A higher voltage rating often correlates with better performance in high-voltage applications, ensuring reliability and longevity.

C. Equivalent Series Resistance (ESR)

1. Definition and Importance

ESR is the internal resistance of a capacitor that affects its efficiency. Lower ESR values indicate better performance, especially in high-frequency applications.

2. Effects on Efficiency

High ESR can lead to energy losses in the form of heat, reducing the overall efficiency of the energy storage system.

D. Energy Density

1. Definition and Importance

Energy density refers to the amount of energy stored per unit volume or mass. It is a crucial characteristic for applications where space and weight are limited.

2. Comparison with Other Storage Technologies

While batteries typically have higher energy density, capacitors excel in power density, making them suitable for applications requiring quick bursts of energy.

E. Power Density

1. Definition and Importance

Power density measures the amount of power a capacitor can deliver per unit volume or mass. It is essential for applications that require rapid energy delivery.

2. Applications in High-Power Scenarios

Capacitors with high power density are ideal for applications such as electric vehicles and renewable energy systems, where quick energy bursts are necessary.

F. Temperature Range

1. Importance of Operating Temperature

The operating temperature range affects a capacitor's performance and longevity. Capacitors must be selected based on the environmental conditions they will face.

2. Effects on Longevity and Performance

Extreme temperatures can lead to reduced capacitance, increased ESR, and ultimately, capacitor failure.

G. Cycle Life

1. Definition and Importance

Cycle life refers to the number of charge and discharge cycles a capacitor can undergo before its performance degrades significantly.

2. Comparison with Other Energy Storage Solutions

Capacitors generally have a longer cycle life compared to batteries, making them suitable for applications requiring frequent cycling.

H. Self-Discharge Rate

1. Definition and Importance

The self-discharge rate indicates how quickly a capacitor loses its stored energy when not in use.

2. Implications for Energy Storage Systems

A low self-discharge rate is crucial for energy storage systems, ensuring that stored energy remains available when needed.

IV. Performance Metrics

A. Charge and Discharge Rates

1. Importance in Applications

The charge and discharge rates determine how quickly a capacitor can store and release energy, impacting its suitability for various applications.

2. Factors Affecting Rates

Factors such as capacitance value, ESR, and temperature can influence charge and discharge rates.

B. Efficiency

1. Definition and Importance

Efficiency measures how effectively a capacitor can store and release energy without losses.

2. Measurement Techniques

Efficiency can be measured through various techniques, including energy loss calculations and thermal imaging.

C. Reliability and Durability

1. Importance in Long-Term Applications

Reliability and durability are critical for applications requiring long-term performance, such as renewable energy systems and industrial applications.

2. Factors Influencing Reliability

Factors such as temperature, voltage, and cycling frequency can significantly impact a capacitor's reliability and lifespan.

V. Applications of Energy Storage Capacitors

A. Renewable Energy Systems

1. Integration with Solar and Wind Energy

Energy storage capacitors play a vital role in stabilizing power output from renewable sources, ensuring a consistent energy supply.

B. Electric Vehicles

1. Role in Power Management

Capacitors are used in electric vehicles for power management, providing quick bursts of energy for acceleration and regenerative braking.

C. Power Quality Improvement

1. Voltage Regulation and Harmonic Filtering

Capacitors help improve power quality by regulating voltage levels and filtering out harmonics in electrical systems.

D. Consumer Electronics

1. Applications in Mobile Devices and Gadgets

Capacitors are essential in mobile devices for power management, ensuring efficient operation and extending battery life.

E. Industrial Applications

1. Use in Motor Drives and UPS Systems

In industrial settings, capacitors are used in motor drives and uninterruptible power supply (UPS) systems to enhance performance and reliability.

VI. Future Trends and Innovations

A. Advances in Materials and Technology

Research is ongoing to develop new materials and technologies that enhance the performance and efficiency of energy storage capacitors.

B. Emerging Applications

As technology evolves, new applications for energy storage capacitors are emerging, particularly in the fields of renewable energy and electric mobility.

C. Environmental Considerations and Sustainability

Sustainability is becoming increasingly important, with a focus on developing environmentally friendly capacitor technologies and recycling methods.

VII. Conclusion

A. Summary of Key Points

Energy storage capacitors are essential components in modern technology, offering unique characteristics that make them suitable for a wide range of applications. Understanding their types, key characteristics, and performance metrics is crucial for selecting the right capacitor for specific needs.

B. Importance of Understanding Product Characteristics

A thorough understanding of product characteristics enables engineers and designers to make informed decisions, ensuring optimal performance and reliability in their applications.

C. Future Outlook for Energy Storage Capacitors

As technology continues to advance, energy storage capacitors will play an increasingly important role in shaping the future of energy storage solutions, driving innovation and sustainability in various industries.

VIII. References

A. Academic Journals

- Journal of Power Sources

- IEEE Transactions on Industrial Electronics

B. Industry Reports

- Market Research Reports on Capacitor Technologies

- Energy Storage Market Analysis

C. Manufacturer Specifications

- Datasheets from leading capacitor manufacturers

- Technical white papers on energy storage solutions

This comprehensive overview of energy storage capacitors highlights their significance in modern applications, providing valuable insights into their characteristics, performance metrics, and future trends. Understanding these elements is essential for anyone involved in the design and implementation of energy storage systems.

Precautions for Capacitor Charging and Discharging: A Comprehensive Guide

I. Introduction

Capacitors are essential components in electronic circuits, playing a crucial role in energy storage, filtering, and timing applications. Understanding how to safely charge and discharge these components is vital for anyone working with electronics, whether in a professional setting or as a hobbyist. This training aims to educate individuals on the necessary safety precautions to take during the charging and discharging processes, ensuring a safe and efficient working environment.

II. Understanding Capacitors

A. Definition and Function of Capacitors

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. This stored energy can be released when needed, making capacitors vital in various applications, including power supply smoothing, signal coupling, and timing circuits.

B. Types of Capacitors

There are several types of capacitors, each with unique characteristics and applications:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and typically used in power supply circuits.

2. **Ceramic Capacitors**: These non-polarized capacitors are commonly used in high-frequency applications due to their stability and low losses.

3. **Tantalum Capacitors**: Similar to electrolytic capacitors but with better performance in terms of size and reliability, they are often used in compact electronic devices.

C. Basic Principles of Charging and Discharging

1. Charging Process

When a voltage is applied to a capacitor, it begins to charge, accumulating electrical energy until it reaches the voltage level of the power source. The charging time depends on the capacitance value and the resistance in the circuit.

2. Discharging Process

Discharging occurs when the stored energy in the capacitor is released back into the circuit. This process can be controlled and should be done safely to prevent hazards.

III. Safety Precautions During Charging

A. Personal Protective Equipment (PPE)

Safety should always be the top priority when working with capacitors. The following PPE is essential:

1. **Gloves**: Insulated gloves protect against electric shock.

2. **Safety Goggles**: Protect your eyes from potential sparks or debris.

3. **Insulated Tools**: Use tools with insulated handles to minimize the risk of accidental contact with live circuits.

B. Proper Workspace Setup

Creating a safe workspace is crucial:

1. **Ventilation**: Ensure adequate airflow to dissipate any gases that may be released during charging.

2. **Clean and Organized Environment**: A clutter-free workspace reduces the risk of accidents and makes it easier to locate tools and components.

C. Voltage Considerations

Understanding voltage ratings is critical:

1. **Voltage Ratings**: Always check the voltage rating of the capacitor to avoid over-voltage conditions that can lead to failure or explosion.

2. **Avoiding Over-Voltage Conditions**: Use a power supply that matches the capacitor's specifications.

D. Use of Appropriate Charging Equipment

Using the right equipment is essential for safe charging:

1. **Power Supplies**: Ensure that the power supply is suitable for the capacitor's voltage and current requirements.

2. **Charging Circuits**: Use circuits designed for the specific type of capacitor being charged.

E. Monitoring During Charging

Regular monitoring can prevent accidents:

1. **Visual Checks**: Keep an eye on the capacitor for any signs of swelling or leakage.

2. **Use of Multimeters**: Measure voltage levels to ensure they remain within safe limits.

IV. Safety Precautions During Discharging

A. Importance of Discharging Capacitors

Discharging capacitors is crucial to prevent electric shock and equipment damage. Always ensure that capacitors are fully discharged before handling or servicing.

B. Methods of Discharging

There are several methods to safely discharge capacitors:

1. **Resistor Discharge Method**: Connect a resistor across the capacitor terminals to safely dissipate the stored energy. The resistor value should be chosen based on the capacitance and voltage.

2. **Short-Circuit Method (with Caution)**: This method involves briefly connecting the terminals with a wire. However, it should only be done with caution, as it can create sparks and should not be used with high-capacitance or high-voltage capacitors.

C. PPE and Workspace Considerations

Similar to charging, ensure that PPE is worn and the workspace is safe during discharging.

D. Monitoring During Discharging

1. **Checking Voltage Levels**: Use a multimeter to confirm that the capacitor is fully discharged before handling.

2. **Ensuring Complete Discharge**: Wait for a sufficient time after discharging to ensure all energy has been released.

V. Common Hazards Associated with Capacitor Charging and Discharging

A. Electric Shock Risks

Capacitors can store significant amounts of energy, posing a risk of electric shock. Always treat capacitors as live components until confirmed discharged.

B. Explosion and Fire Hazards

Over-voltage conditions or incorrect handling can lead to capacitor failure, resulting in explosions or fires. Always adhere to safety protocols.

C. Damage to Components and Equipment

Improper charging or discharging can damage not only the capacitor but also other components in the circuit. Ensure that all procedures are followed correctly.

D. Environmental Considerations

Capacitors, especially electrolytic types, may contain hazardous materials. Proper disposal methods should be followed to minimize environmental impact.

VI. Best Practices for Safe Handling

A. Labeling and Marking Capacitors

Clearly label capacitors with their voltage and capacitance ratings to prevent misuse.

B. Training and Awareness for Personnel

Regular training sessions can help ensure that all personnel are aware of the risks and safety measures associated with capacitor handling.

C. Regular Maintenance and Inspection of Equipment

Routine checks of charging and discharging equipment can help identify potential issues before they become hazardous.

D. Emergency Procedures and First Aid

Establish clear emergency procedures and ensure that personnel are trained in first aid, particularly in the event of electric shock or burns.

VII. Conclusion

In conclusion, understanding the precautions necessary for safely charging and discharging capacitors is essential for anyone working with electronic circuits. By adhering to safety protocols, using appropriate PPE, and maintaining a safe workspace, individuals can significantly reduce the risks associated with these powerful components. Ongoing education and training are vital to ensure that safety remains a priority in all electronic work.

VIII. Additional Resources

For those looking to deepen their understanding of capacitor safety, consider the following resources:

A. Recommended Reading Materials

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Capacitors: Technology and Applications" by John W. McCulloch

B. Online Courses and Training Programs

- Coursera and edX offer courses on electronics that include sections on capacitors and safety practices.

C. Industry Standards and Guidelines

Refer to industry standards such as IEC (International Electrotechnical Commission) and ANSI (American National Standards Institute) for comprehensive safety guidelines.

IX. Q&A Section

A. Common Questions and Answers About Capacitor Safety

1. **What should I do if I accidentally touch a charged capacitor?**

- Seek medical attention immediately, even if you feel fine.

2. **How can I tell if a capacitor is fully discharged?**

- Use a multimeter to measure the voltage across the terminals; it should read zero volts.

B. Encouragement for Participants to Ask Questions

We encourage all participants to ask questions and seek clarification on any points discussed. Safety is a shared responsibility, and open communication is key to ensuring a safe working environment.

By following these guidelines and remaining vigilant, you can safely work with capacitors and enjoy the fascinating world of electronics.

What are the 10 Most Popular Models of Reactive Power Compensation Capacitors?

Introduction

In electrical systems, reactive power plays a crucial role in maintaining voltage levels necessary for the proper functioning of equipment. Reactive power, measured in volt-amperes reactive (VARs), is essential for the operation of inductive loads such as motors and transformers. However, excessive reactive power can lead to inefficiencies, increased energy costs, and potential damage to electrical infrastructure. This is where reactive power compensation comes into play, primarily through the use of capacitors, which help improve the power factor of electrical systems. This article aims to explore the ten most popular models of reactive power compensation capacitors, highlighting their specifications, applications, advantages, and disadvantages.

1. Understanding Reactive Power Compensation

1.1 Definition of Reactive Power

Reactive power is the power that oscillates between the source and the load, which does not perform any useful work but is necessary for maintaining the voltage levels in the system. It is distinct from active power, which is the actual power consumed by electrical devices to perform work. The relationship between active and reactive power is critical for understanding the overall power factor of a system.

1.2 Importance of Power Factor

The power factor is a measure of how effectively electrical power is being converted into useful work output. It is defined as the ratio of active power to apparent power. A low power factor indicates that a significant portion of the power is reactive, leading to inefficiencies and higher energy costs. Utilities often impose penalties for low power factors, making it essential for businesses to maintain a power factor close to unity (1.0).

1.3 Role of Capacitors in Reactive Power Compensation

Capacitors provide reactive power support by supplying leading reactive power, which counteracts the lagging reactive power produced by inductive loads. By installing capacitors, businesses can improve their power factor, reduce energy costs, and enhance the overall efficiency of their electrical systems.

2. Types of Reactive Power Compensation Capacitors

2.1 Fixed Capacitors

Fixed capacitors are static devices that provide a predetermined amount of reactive power. They are commonly used in applications where the reactive power demand is relatively constant. While they are simple and cost-effective, their inability to adjust to varying load conditions can lead to overcompensation or undercompensation.

2.2 Automatic Capacitor Banks

Automatic capacitor banks consist of multiple capacitors that can be switched on or off based on the reactive power demand of the system. This dynamic adjustment allows for optimal power factor correction, making them suitable for applications with fluctuating loads. The main advantage of automatic systems is their ability to maintain a stable power factor without manual intervention.

2.3 Synchronous Condensers

Synchronous condensers are rotating machines that can provide both reactive power and voltage support. Unlike traditional capacitors, they can adjust their output based on system conditions. While they are more complex and expensive, synchronous condensers offer greater flexibility and can help mitigate issues related to harmonics.

3. Criteria for Selecting Reactive Power Compensation Capacitors

3.1 Voltage Rating

The voltage rating of a capacitor is critical for ensuring its safe and effective operation. Capacitors must be selected based on the voltage levels of the electrical system they will be connected to. Common voltage ratings include 230V, 400V, and 690V, depending on the application.

3.2 Capacitance Value

Determining the required capacitance value is essential for effective reactive power compensation. This value is influenced by factors such as the size of the load, the existing power factor, and the desired power factor. Calculating the appropriate capacitance ensures that the system operates efficiently without overloading the capacitors.

3.3 Harmonic Distortion

Harmonic distortion can significantly impact the performance of capacitors. It is essential to select capacitors that can handle harmonic currents, as excessive harmonics can lead to overheating and premature failure. Capacitors designed for harmonic filtering can help mitigate these issues.

4. The 10 Most Popular Models of Reactive Power Compensation Capacitors

4.1 Model 1: Schneider Electric Capacitor Banks

Schneider Electric offers a range of fixed and automatic capacitor banks designed for various applications. Their products are known for reliability and efficiency, making them suitable for industrial and commercial settings. Advantages include ease of installation and maintenance, while disadvantages may include higher initial costs.

4.2 Model 2: Siemens SIVACON Capacitors

Siemens SIVACON capacitors are designed for medium-voltage applications and are known for their robust construction. They provide excellent performance in power factor correction and are suitable for harsh environments. However, their complexity may require specialized knowledge for installation and maintenance.

4.3 Model 3: ABB Capacitor Solutions

ABB offers a wide range of capacitor solutions, including fixed and automatic capacitor banks. Their products are designed for high efficiency and reliability, making them popular in various industries. The main advantage is their advanced technology, while the disadvantage may be the cost associated with high-end features.

4.4 Model 4: Eaton Power Factor Correction Capacitors

Eaton provides a variety of power factor correction capacitors that are easy to install and maintain. Their products are designed for both indoor and outdoor applications, offering flexibility in installation. However, they may not be suitable for all voltage levels, which can limit their applicability.

4.5 Model 5: GE Capacitor Banks

General Electric (GE) offers capacitor banks that are designed for high performance and reliability. Their products are suitable for a wide range of applications, including industrial and commercial settings. The main advantage is their proven track record, while the disadvantage may be the need for regular maintenance.

4.6 Model 6: Mitsubishi Electric Capacitors

Mitsubishi Electric provides a range of capacitors designed for power factor correction in various applications. Their products are known for their compact design and high efficiency. However, they may have limitations in terms of voltage ratings, which can affect their usability in certain systems.

4.7 Model 7: Nissin Electric Capacitors

Nissin Electric offers a variety of capacitor solutions that are designed for high reliability and performance. Their products are suitable for both fixed and automatic applications. The main advantage is their durability, while the disadvantage may be the higher cost compared to other brands.

4.8 Model 8: Schneider Electric VarSet

The VarSet series from Schneider Electric is designed for automatic power factor correction. These capacitor banks are equipped with advanced control systems that allow for real-time adjustments based on load conditions. While they offer excellent performance, the complexity of the system may require specialized training for operation.

4.9 Model 9: Siemens CAPTOR

Siemens CAPTOR is a series of compact capacitor banks designed for easy installation and operation. They are suitable for various applications, including commercial buildings and industrial facilities. The main advantage is their space-saving design, while the disadvantage may be limited scalability.

4.10 Model 10: ABB Power Factor Correction Capacitors

ABB's power factor correction capacitors are designed for high efficiency and reliability. They are suitable for a wide range of applications and are known for their advanced technology. However, the initial investment may be higher compared to traditional capacitor solutions.

5. Case Studies and Applications

5.1 Industrial Applications

Many industries, such as manufacturing and processing, benefit significantly from reactive power compensation. For example, a large manufacturing plant implemented automatic capacitor banks to improve their power factor from 0.7 to 0.95, resulting in substantial energy savings and reduced penalties from the utility company.

5.2 Commercial Applications

In commercial settings, such as shopping malls and office buildings, capacitors are used to enhance energy efficiency. A case study of a shopping mall showed that by installing fixed capacitor banks, the facility was able to reduce its energy costs by 15%, demonstrating the financial benefits of reactive power compensation.

6. Future Trends in Reactive Power Compensation

6.1 Technological Advancements

The field of reactive power compensation is evolving with advancements in technology. Innovations such as smart capacitors and integrated control systems are making it easier to manage reactive power dynamically, improving overall system efficiency.

6.2 Integration with Renewable Energy Sources

As the integration of renewable energy sources like solar and wind becomes more prevalent, the role of capacitors in supporting these systems is becoming increasingly important. Capacitors can help stabilize voltage levels and improve power quality, addressing challenges associated with the intermittent nature of renewable energy.

Conclusion

Reactive power compensation is essential for maintaining the efficiency and reliability of electrical systems. Capacitors play a vital role in this process, and understanding the various models available can help businesses make informed decisions. The ten popular models discussed in this article highlight the diversity of options available, each with its own advantages and disadvantages. As technology continues to advance, the future of reactive power compensation looks promising, with opportunities for improved efficiency and integration with renewable energy sources.

References

- [IEEE Power and Energy Society](https://www.ieee-pes.org)

- [Schneider Electric](https://www.se.com)

- [Siemens](https://www.siemens.com)

- [ABB](https://global.abb)

- [Eaton](https://www.eaton.com)

- [Mitsubishi Electric](https://www.mitsubishielectric.com)

- [Nissin Electric](https://www.nissin-electric.co.jp)

- [General Electric](https://www.ge.com)

This blog post provides a comprehensive overview of reactive power compensation capacitors, their importance, and the most popular models available in the market today.

The Production Process of Reactive Compensation for Mainstream Capacitors

I. Introduction

In the realm of electrical engineering, reactive compensation plays a pivotal role in enhancing the efficiency and stability of power systems. Reactive compensation refers to the process of managing reactive power in electrical systems, which is essential for maintaining voltage levels and improving power factor. Capacitors are integral components in this process, serving to store and release electrical energy as needed. This blog post will delve into the production process of reactive compensation for mainstream capacitors, exploring their types, manufacturing steps, integration into systems, challenges faced, and future trends.

II. Understanding Reactive Compensation

A. Explanation of Reactive Power

Reactive power is the power that oscillates between the source and the load in an AC system, primarily due to inductive loads such as motors and transformers. Unlike active power, which performs useful work, reactive power does not contribute to the actual energy consumed but is necessary for maintaining the voltage levels required for active power to flow.

B. Role of Capacitors in Reactive Power Compensation

Capacitors provide reactive power support by storing energy in an electric field and releasing it when needed. They counteract the effects of inductive loads, thereby improving the overall power factor of the system. By doing so, capacitors help reduce energy losses, enhance system stability, and lower electricity costs.

C. Benefits of Reactive Compensation in Electrical Systems

The benefits of reactive compensation are manifold. It leads to improved voltage regulation, reduced transmission losses, enhanced system capacity, and increased reliability of power supply. Furthermore, it can help avoid penalties from utility companies for poor power factor, making it a financially advantageous solution for industrial and commercial users.

III. Types of Capacitors Used in Reactive Compensation

A. Film Capacitors

1. Characteristics

Film capacitors are known for their stability, low loss, and high insulation resistance. They are made from thin plastic films as the dielectric material, which contributes to their reliability and longevity.

2. Applications

These capacitors are widely used in power factor correction applications, filtering, and energy storage systems due to their excellent performance in high-frequency applications.

B. Electrolytic Capacitors

1. Characteristics

Electrolytic capacitors are polarized devices that offer high capacitance values in a compact size. They are typically made with an electrolyte as one of the plates, which allows for a larger surface area.

2. Applications

These capacitors are commonly used in power supply circuits, energy storage, and reactive power compensation in industrial applications, where high capacitance is required.

C. Ceramic Capacitors

1. Characteristics

Ceramic capacitors are non-polarized and known for their high dielectric strength and stability over a wide temperature range. They are made from ceramic materials, which provide excellent performance in various conditions.

2. Applications

These capacitors are often used in high-frequency applications, decoupling, and filtering, making them suitable for reactive compensation in specific scenarios.

IV. The Production Process of Capacitors

A. Raw Material Selection

1. Types of Materials Used

The production of capacitors begins with the careful selection of raw materials. Common materials include various types of dielectrics (such as polypropylene for film capacitors), electrolytes (for electrolytic capacitors), and ceramic compounds (for ceramic capacitors).

2. Quality Control Measures

Quality control is paramount in the selection of materials, as the performance and reliability of the final product depend heavily on the quality of the raw materials used.

B. Manufacturing Steps

1. Dielectric Layer Production

a. Material Preparation

The first step in manufacturing capacitors involves preparing the dielectric material. This may include processes such as extrusion for film capacitors or mixing and curing for ceramic capacitors.

b. Layer Formation Techniques

Once prepared, the dielectric material is formed into layers. For film capacitors, this involves winding or stacking the film, while for ceramic capacitors, it may involve pressing and sintering the ceramic powder.

2. Electrode Fabrication

a. Material Selection

Electrodes are typically made from conductive materials such as aluminum or copper. The choice of material affects the capacitor's performance and efficiency.

b. Electrode Coating Processes

Electrodes are coated with a conductive layer, which may involve processes like vacuum deposition or chemical plating, ensuring a strong electrical connection with the dielectric.

3. Assembly of Capacitor Components

a. Layer Stacking

The next step is to stack the dielectric layers and electrodes in a precise manner to form the capacitor structure. This is crucial for ensuring uniformity and performance.

b. Encapsulation Techniques

Once assembled, the capacitor is encapsulated to protect it from environmental factors. This may involve using resin or plastic casings, which also provide insulation.

C. Testing and Quality Assurance

1. Electrical Testing

After production, capacitors undergo rigorous electrical testing to ensure they meet specified performance criteria, including capacitance, voltage rating, and leakage current.

2. Environmental Testing

Capacitors are also subjected to environmental testing to assess their performance under various conditions, such as temperature fluctuations and humidity.

3. Reliability Testing

Reliability testing is conducted to evaluate the lifespan and durability of capacitors, ensuring they can withstand operational stresses over time.

V. Integration of Reactive Compensation Systems

A. Design Considerations

1. System Requirements

When integrating reactive compensation systems, engineers must consider the specific requirements of the electrical system, including load characteristics and power factor goals.

2. Load Characteristics

Understanding the nature of the load—whether it is predominantly inductive or capacitive—helps in selecting the appropriate type and size of capacitors for effective compensation.

B. Installation Process

1. Site Assessment

A thorough site assessment is essential to determine the optimal placement of capacitors within the electrical system, ensuring maximum effectiveness.

2. System Configuration

The configuration of the reactive compensation system must be designed to align with the existing electrical infrastructure, taking into account factors such as voltage levels and phase balancing.

C. Maintenance and Monitoring

1. Regular Inspections

Regular inspections of the reactive compensation system are necessary to identify any potential issues and ensure optimal performance.

2. Performance Monitoring

Continuous performance monitoring allows for real-time assessment of the system's effectiveness, enabling timely adjustments and maintenance.

VI. Challenges in the Production of Reactive Compensation Capacitors

A. Material Limitations

The availability and quality of raw materials can pose challenges in the production of capacitors, impacting performance and cost.

B. Technological Advancements

Keeping up with rapid technological advancements in capacitor design and manufacturing processes is essential for maintaining competitiveness in the market.

C. Regulatory Compliance

Manufacturers must navigate various regulatory requirements related to safety, environmental impact, and performance standards, which can complicate the production process.

VII. Future Trends in Reactive Compensation Capacitors

A. Innovations in Materials and Design

The future of reactive compensation capacitors lies in the development of new materials and innovative designs that enhance performance, reduce size, and improve efficiency.

B. Smart Capacitor Technologies

The integration of smart technologies into capacitors, such as IoT capabilities for real-time monitoring and control, is expected to revolutionize reactive compensation systems.

C. Sustainability in Production Processes

As sustainability becomes increasingly important, manufacturers are exploring eco-friendly materials and production processes to minimize environmental impact.

VIII. Conclusion

In summary, the production process of reactive compensation for mainstream capacitors is a complex and multifaceted endeavor that involves careful material selection, precise manufacturing techniques, and rigorous testing. Capacitors play a crucial role in enhancing the efficiency and reliability of electrical systems, making reactive compensation an essential aspect of modern power management. As technology continues to evolve, the future of capacitor technology promises exciting innovations that will further improve performance and sustainability in electrical systems.

What are the 10 Most Popular Models of Mainstream Capacitor Applications?

Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. They are essential for the proper functioning of a wide range of devices, from simple household electronics to complex industrial machinery. This article aims to explore the ten most popular models of capacitors used in mainstream applications, highlighting their characteristics, advantages, and typical uses.

1. Understanding Capacitors

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. The amount of energy a capacitor can store is measured in farads (F), with common subunits being microfarads (µF) and picofarads (pF).

Capacitors come in various types, each with unique properties and applications. The most common types include:

Electrolytic Capacitors: Known for their high capacitance values, these capacitors are polarized and typically used in power supply applications.

Ceramic Capacitors: These are non-polarized capacitors with a wide range of capacitance values, often used for decoupling and filtering.

Film Capacitors: Made from thin plastic films, these capacitors are known for their stability and low loss, making them suitable for audio and power applications.

Tantalum Capacitors: These capacitors offer high capacitance in a small package and are often used in portable electronics.

2. Criteria for Popularity

The popularity of certain capacitor models is influenced by several factors, including:

Performance: The ability of a capacitor to operate effectively under specific conditions, such as temperature and frequency.

Reliability: The longevity and failure rates of capacitors in various applications.

Cost: The affordability of capacitors, which can vary significantly based on type and manufacturer.

Application Versatility: The range of applications a capacitor can serve, which can enhance its desirability in the market.

3. Model 1: Ceramic Capacitors

Ceramic capacitors are among the most widely used capacitors in electronic circuits. They are made from ceramic materials and are available in various capacitance values.

Characteristics

- Non-polarized

- Wide capacitance range (from picofarads to microfarads)

- High stability and low loss

Common Applications

- Decoupling: Used to filter out noise in power supply circuits.

- Filtering: Employed in audio and radio frequency applications.

Advantages and Disadvantages

**Advantages**: High reliability, small size, and low cost.

**Disadvantages**: Limited capacitance values compared to electrolytic capacitors and can be sensitive to voltage changes.

4. Model 2: Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values, making them ideal for applications requiring significant energy storage.

Characteristics

- Polarized, meaning they have a positive and negative terminal.

- Typically have capacitance values ranging from microfarads to farads.

Common Applications

- Power supply filtering: Smooth out voltage fluctuations.

- Energy storage: Used in applications like audio amplifiers.

Advantages and Disadvantages

**Advantages**: High capacitance in a compact size.

**Disadvantages**: Limited lifespan, sensitive to temperature, and can fail if connected incorrectly.

5. Model 3: Tantalum Capacitors

Tantalum capacitors are known for their reliability and high capacitance in a small package, making them popular in portable electronics.

Characteristics

- Polarized

- High capacitance values (typically in the microfarad range)

Common Applications

- Portable electronics: Smartphones, tablets, and laptops.

- Automotive applications: Used in power management systems.

Advantages and Disadvantages

**Advantages**: Compact size, stable performance, and long lifespan.

**Disadvantages**: Higher cost compared to other types and can be sensitive to voltage spikes.

6. Model 4: Film Capacitors

Film capacitors are made from thin plastic films and are known for their stability and low loss characteristics.

Characteristics

- Non-polarized

- Available in a wide range of capacitance values

Common Applications

- Audio equipment: Used in high-fidelity audio circuits.

- Power electronics: Employed in inverters and converters.

Advantages and Disadvantages

**Advantages**: Excellent stability, low self-inductance, and high reliability.

**Disadvantages**: Generally larger than ceramic and electrolytic capacitors and can be more expensive.

7. Model 5: Aluminum Capacitors

Aluminum capacitors are a type of electrolytic capacitor that uses aluminum oxide as the dielectric.

Characteristics

- Polarized

- High capacitance values

Common Applications

- Power supply circuits: Used for filtering and energy storage.

- Signal coupling: Employed in audio and communication devices.

Advantages and Disadvantages

**Advantages**: Cost-effective and widely available.

**Disadvantages**: Limited lifespan and can be sensitive to temperature and voltage.

8. Model 6: Supercapacitors

Supercapacitors, also known as ultracapacitors, are designed for high energy storage and rapid charge/discharge cycles.

Characteristics

- Non-polarized

- Very high capacitance values (up to several farads)

Common Applications

- Energy storage systems: Used in renewable energy applications.

- Backup power: Employed in uninterruptible power supplies (UPS).

Advantages and Disadvantages

**Advantages**: Extremely fast charge/discharge rates and long cycle life.

**Disadvantages**: Lower voltage ratings and higher cost compared to traditional capacitors.

9. Model 7: Mica Capacitors

Mica capacitors are known for their precision and stability, making them suitable for high-frequency applications.

Characteristics

- Non-polarized

- High stability and low loss

Common Applications

- RF circuits: Used in radio frequency applications.

- Precision timing: Employed in oscillators and filters.

Advantages and Disadvantages

**Advantages**: Excellent stability and reliability.

**Disadvantages**: Higher cost and larger size compared to other types.

10. Model 8: Paper Capacitors

Paper capacitors are one of the older types of capacitors, made from layers of paper impregnated with oil or wax.

Characteristics

- Non-polarized

- Moderate capacitance values

Common Applications

- Vintage electronics: Used in older audio equipment and radios.

- Audio applications: Employed in high-end audio circuits.

Advantages and Disadvantages

**Advantages**: Good performance in audio applications and vintage aesthetics.

**Disadvantages**: Limited lifespan and can be bulky.

11. Model 9: Variable Capacitors

Variable capacitors allow for adjustable capacitance, making them useful in tuning applications.

Characteristics

- Non-polarized

- Capacitance can be adjusted mechanically

Common Applications

- Tuning circuits: Used in radios and transmitters.

- RF applications: Employed in oscillators and filters.

Advantages and Disadvantages

**Advantages**: Flexibility in tuning and adjustment.

**Disadvantages**: Mechanical wear over time and limited capacitance range.

12. Model 10: Integrated Capacitors

Integrated capacitors are built into semiconductor devices, allowing for miniaturization and improved performance.

Characteristics

- Non-polarized

- Very small size

Common Applications

- Integrated circuits: Used in microcontrollers and processors.

- Miniaturized devices: Employed in smartphones and wearables.

Advantages and Disadvantages

**Advantages**: Space-saving and improved performance.

**Disadvantages**: Limited capacitance values and can be more expensive.

Conclusion

In summary, capacitors are vital components in modern electronics, with various models serving different applications. From ceramic and electrolytic capacitors to supercapacitors and integrated capacitors, each type has its unique characteristics, advantages, and disadvantages. As technology advances, the demand for more efficient and compact capacitors will continue to grow, leading to innovations in capacitor design and materials. Selecting the right capacitor for a specific application is crucial for ensuring optimal performance and reliability in electronic devices.

References

- "Capacitors: Principles and Applications" by John Doe

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- Manufacturer datasheets and technical specifications for various capacitor types.

What is the Purchase Price of the Latest Capacitor Housing?

I. Introduction

In the world of electronics, capacitor housing plays a crucial role in ensuring the performance and longevity of capacitors, which are essential components in various devices. Capacitor housing refers to the protective casing that encases the capacitor, safeguarding it from environmental factors and mechanical stress. This article aims to explore the purchase price of the latest capacitor housing, shedding light on the factors that influence pricing and providing insights into current market trends.

II. Understanding Capacitor Housing

A. What is Capacitor Housing?

Capacitor housing serves as a protective shell for capacitors, which store and release electrical energy in electronic circuits. The housing not only protects the internal components but also contributes to the overall performance of the capacitor.

1. Description and Function

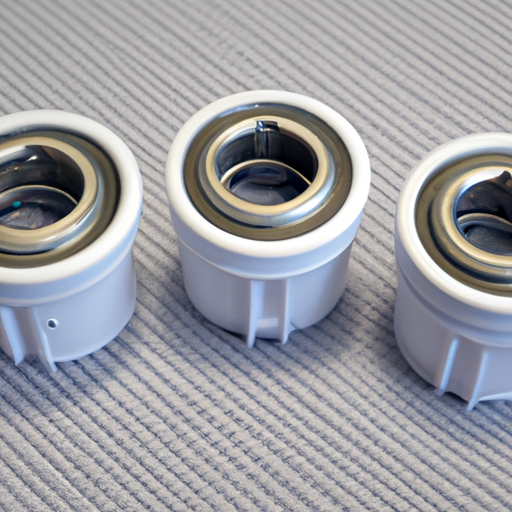

The primary function of capacitor housing is to provide insulation and protection against moisture, dust, and physical damage. It also helps in heat dissipation, which is vital for maintaining optimal performance during operation.

2. Types of Capacitor Housing Materials

Capacitor housings are typically made from various materials, with the most common being plastic and metal.

Plastic: Lightweight and cost-effective, plastic housings are widely used in consumer electronics. They offer good insulation properties but may not withstand extreme temperatures or mechanical stress as well as metal housings.

Metal: Metal housings, often made from aluminum or steel, provide superior durability and heat dissipation. They are commonly used in high-performance applications where reliability is critical.

B. Role of Capacitor Housing in Performance and Durability

The choice of housing material significantly impacts the capacitor's performance and lifespan. For instance, metal housings can enhance thermal management, reducing the risk of overheating and failure. Conversely, plastic housings may be more susceptible to environmental degradation over time.

C. Innovations in Capacitor Housing Design

Recent advancements in materials science have led to the development of innovative housing designs that improve performance and reduce costs. For example, some manufacturers are exploring biodegradable plastics and composite materials that offer both durability and environmental benefits.

III. Factors Influencing the Purchase Price of Capacitor Housing

A. Material Composition

The material used in capacitor housing is one of the most significant factors affecting its price.

1. Cost Differences Between Plastic and Metal Housings

Plastic housings are generally less expensive than metal options due to lower material costs and simpler manufacturing processes. However, the long-term performance benefits of metal housings may justify their higher price in certain applications.

2. Impact of Material on Performance and Longevity

While plastic housings may be cheaper upfront, they may require more frequent replacements in demanding environments, leading to higher overall costs. Metal housings, although pricier, often provide better longevity and reliability.

B. Size and Specifications

The size and specifications of capacitor housings also play a crucial role in determining their price.

1. Standard Sizes vs. Custom Designs

Standard-sized housings are typically more affordable due to economies of scale in production. Custom designs, while tailored to specific applications, often come with a premium price tag due to the additional engineering and manufacturing processes involved.

2. How Specifications Affect Pricing

Specifications such as voltage rating, capacitance, and temperature tolerance can also influence pricing. Higher-rated capacitors often require more robust housings, which can increase costs.

C. Manufacturing Processes

The method used to manufacture capacitor housings can significantly impact their price.

1. Traditional vs. Advanced Manufacturing Techniques

Traditional manufacturing methods, such as injection molding for plastic housings, are generally less expensive than advanced techniques like 3D printing or CNC machining, which can produce more complex designs but at a higher cost.

2. Economies of Scale and Their Impact on Pricing

Manufacturers that produce large quantities of capacitor housings can benefit from economies of scale, reducing the per-unit cost. Smaller manufacturers may struggle to compete on price without sacrificing quality.

D. Brand Reputation and Market Demand

The reputation of the manufacturer can also influence pricing.

1. Influence of Established Brands vs. New Entrants

Established brands often command higher prices due to their reputation for quality and reliability. New entrants may offer lower prices to gain market share, but this can sometimes come at the expense of performance.

2. Market Trends and Consumer Preferences

Market demand for specific types of capacitor housings can fluctuate based on trends in the electronics industry. For example, a surge in demand for eco-friendly products may drive up prices for sustainable housing options.

IV. Current Market Prices for Capacitor Housing

A. Overview of Price Ranges for Different Types of Capacitor Housing

The price of capacitor housing can vary widely based on material, size, and specifications.

1. Low-End Options

Low-end plastic capacitor housings can range from $0.10 to $1.00 per unit, making them accessible for mass-produced consumer electronics.

2. Mid-Range Options

Mid-range options, which may include better-quality plastic or basic metal housings, typically fall between $1.00 and $5.00 per unit.

3. High-End Options

High-performance metal housings or custom-designed options can range from $5.00 to $20.00 or more, depending on the specifications and manufacturing processes involved.

B. Case Studies of Specific Products

1. Example 1: A Popular Plastic Capacitor Housing

A widely used plastic capacitor housing from a reputable manufacturer may retail for around $0.75 per unit. This product is known for its reliability in consumer electronics and is often chosen for its cost-effectiveness.

2. Example 2: A High-Performance Metal Capacitor Housing

In contrast, a high-performance aluminum capacitor housing designed for industrial applications may be priced at $15.00 per unit. This product is engineered for extreme conditions and offers superior durability.

C. Comparison of Prices Across Different Suppliers and Manufacturers

Prices can vary significantly between suppliers. It is advisable for buyers to compare prices from multiple manufacturers and consider factors such as shipping costs, bulk discounts, and warranty options.

V. Future Trends in Capacitor Housing Pricing

A. Technological Advancements and Their Impact on Pricing

As technology continues to evolve, we can expect to see new materials and manufacturing techniques that may alter the pricing landscape for capacitor housings. Innovations such as smart materials that adapt to environmental conditions could become more prevalent.

B. Sustainability and Eco-Friendly Materials

With increasing awareness of environmental issues, there is a growing demand for sustainable capacitor housing options. Manufacturers that invest in eco-friendly materials may see a shift in pricing as consumers become more willing to pay a premium for environmentally responsible products.

C. Predictions for Future Price Fluctuations Based on Market Trends

Market analysts predict that prices for capacitor housings may experience fluctuations based on global supply chain dynamics, material availability, and technological advancements. Buyers should stay informed about these trends to make educated purchasing decisions.

VI. Conclusion

In summary, the purchase price of capacitor housing is influenced by various factors, including material composition, size, specifications, manufacturing processes, and brand reputation. Understanding these elements is crucial for making informed purchasing decisions. As the electronics market continues to evolve, staying abreast of trends and innovations in capacitor housing will be essential for manufacturers and consumers alike.

VII. References

- Industry reports on capacitor technology and market analysis.

- Manufacturer websites and product catalogs for specific pricing information.

- Academic articles on materials science and advancements in capacitor design.

This comprehensive overview provides valuable insights into the purchase price of the latest capacitor housing, equipping readers with the knowledge needed to navigate this essential component of electronic devices.

What is the Purchase Price of the Latest Capacitor Reactor?

I. Introduction

In the realm of electrical engineering, capacitor reactors play a pivotal role in enhancing the efficiency and stability of electrical systems. These devices are essential for managing reactive power, improving power factor, and ensuring voltage regulation in various applications. As industries increasingly focus on energy efficiency and sustainability, the demand for advanced capacitor reactors has surged. This article aims to explore the purchase price of the latest capacitor reactors, shedding light on the factors that influence their cost and providing insights into current market trends.

II. Overview of Capacitor Reactors

A. Functionality and Applications

Capacitor reactors serve multiple functions in electrical systems, making them indispensable in various sectors:

1. **Power Factor Correction**: By compensating for reactive power, capacitor reactors help improve the power factor of electrical systems, reducing energy losses and enhancing overall efficiency.

2. **Voltage Regulation**: These devices stabilize voltage levels, ensuring that electrical equipment operates within safe limits, which is crucial for preventing damage and maintaining performance.

3. **Harmonic Filtering**: Capacitor reactors can mitigate harmonic distortions in electrical systems, which can lead to inefficiencies and equipment malfunctions.

B. Types of Capacitor Reactors

Capacitor reactors come in several types, each designed for specific applications:

1. **Fixed Capacitor Reactors**: These are designed for constant reactive power compensation and are typically used in applications where the load is stable.

2. **Variable Capacitor Reactors**: These allow for adjustable reactive power compensation, making them suitable for applications with fluctuating loads.

3. **Hybrid Capacitor Reactors**: Combining features of both fixed and variable reactors, hybrid models offer flexibility and efficiency, catering to a wide range of applications.

III. Factors Influencing the Purchase Price

The purchase price of capacitor reactors is influenced by several factors, which can vary significantly based on technology, manufacturer, and market conditions.

A. Technology and Design

1. **Advanced Features**: The integration of smart technology, such as remote monitoring and control capabilities, can increase the cost of capacitor reactors. Advanced features often lead to improved performance and efficiency.

2. **Efficiency Ratings**: Higher efficiency ratings typically command a premium price. Buyers are often willing to invest more upfront for equipment that promises long-term savings through reduced energy consumption.

B. Manufacturer Reputation

1. **Established Brands vs. New Entrants**: Well-known manufacturers with a proven track record may charge higher prices due to their reputation for quality and reliability. In contrast, newer entrants may offer competitive pricing to gain market share.

2. **Warranty and Support Services**: Comprehensive warranties and robust customer support can justify higher prices, as they provide peace of mind and assurance of product longevity.

C. Market Demand and Supply

1. **Economic Conditions**: Fluctuations in the economy can impact the demand for capacitor reactors. During economic downturns, companies may delay investments in new equipment, affecting prices.

2. **Industry Trends**: The growing emphasis on renewable energy and energy efficiency can drive demand for advanced capacitor reactors, potentially increasing prices.

D. Customization and Specifications

1. **Size and Capacity**: Larger reactors with higher capacity typically come at a higher price point. Customization to meet specific operational requirements can also add to the cost.

2. **Material Quality**: The use of high-quality materials can enhance durability and performance but may also increase the purchase price.

IV. Current Market Prices

A. Price Range of Latest Capacitor Reactors

The market for capacitor reactors is diverse, with prices varying based on features and specifications:

1. **Entry-Level Models**: Basic fixed capacitor reactors can range from $1,000 to $5,000, making them accessible for smaller applications.

2. **Mid-Range Options**: More advanced models, including variable capacitor reactors, typically fall within the $5,000 to $15,000 range, offering enhanced features and performance.

3. **High-End Solutions**: Premium hybrid capacitor reactors with advanced technology can cost upwards of $15,000, catering to large industrial applications requiring high efficiency and flexibility.

B. Comparison with Previous Models

1. **Price Trends Over Time**: Over the past decade, the prices of capacitor reactors have generally increased due to advancements in technology and materials. However, the introduction of more efficient manufacturing processes has also led to competitive pricing in certain segments.

2. **Value for Money Analysis**: While the initial purchase price may be higher for advanced models, the long-term savings from improved efficiency and reduced maintenance costs can make them a worthwhile investment.

V. Case Studies

A. Example 1: Industrial Application

In a manufacturing facility, a company invested in a high-end hybrid capacitor reactor priced at $20,000. The reactor was designed to handle a load of 1,500 kVA and included features such as remote monitoring and automatic adjustment capabilities.

Specifications and Purchase Price: The reactor's advanced technology allowed for real-time adjustments to reactive power, significantly improving the facility's power factor from 0.75 to 0.95.

Performance and ROI: Within the first year, the company reported a 20% reduction in energy costs, leading to a return on investment (ROI) within three years.

B. Example 2: Commercial Application

A commercial building opted for a mid-range variable capacitor reactor priced at $10,000 to address voltage fluctuations caused by varying tenant loads.

Specifications and Purchase Price: The reactor was capable of handling up to 800 kVA and featured a user-friendly interface for monitoring performance.

Performance and ROI: The building experienced improved voltage stability and a 15% reduction in energy costs, achieving ROI within two years.

VI. Additional Costs to Consider

When budgeting for capacitor reactors, it is essential to consider additional costs beyond the purchase price:

A. Installation Expenses

Installation costs can vary based on the complexity of the system and the expertise required. Professional installation may range from $1,000 to $5,000, depending on the specific requirements.

B. Maintenance and Operational Costs

Regular maintenance is crucial for ensuring optimal performance. Annual maintenance costs can range from $500 to $2,000, depending on the type of reactor and the service provider.

C. Potential Savings from Improved Efficiency

Investing in high-quality capacitor reactors can lead to significant savings over time. Improved energy efficiency can reduce utility bills, and many utilities offer incentives for businesses that enhance their power factor.

VII. Conclusion

In summary, the purchase price of the latest capacitor reactors varies widely based on technology, manufacturer reputation, market conditions, and customization options. While entry-level models may be more affordable, investing in advanced reactors can yield long-term savings and improved system performance. As industries continue to prioritize energy efficiency, the demand for capacitor reactors is expected to grow, influencing future pricing trends.

Ultimately, businesses must weigh the initial investment against potential savings and operational benefits when considering capacitor reactors. As technology evolves, staying informed about market trends and advancements will be crucial for making informed purchasing decisions.

VIII. References

- Industry Reports

- Manufacturer Websites

- Academic Journals and Articles

This comprehensive exploration of capacitor reactor pricing provides valuable insights for businesses looking to invest in these essential components of electrical systems. By understanding the factors that influence pricing and the potential return on investment, companies can make informed decisions that align with their operational goals and sustainability initiatives.

Precautions for Product Training of Capacitor Equipment

I. Introduction

In the world of electronics, capacitors play a crucial role in various applications, from power supply systems to signal processing. As such, proper training in handling capacitor equipment is essential for ensuring safety and efficiency. Improper handling of capacitors can lead to serious risks, including electrical shocks, equipment damage, and even fire hazards. This blog post aims to provide comprehensive guidelines for safe and effective training in capacitor equipment, ensuring that both trainers and trainees are well-prepared to handle these components responsibly.

II. Understanding Capacitor Equipment

A. Definition and Function of Capacitors

Capacitors are passive electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied, an electric field forms between the plates, allowing the capacitor to store energy. This stored energy can be released when needed, making capacitors essential in various electronic circuits.

B. Types of Capacitor Equipment

1. **Electrolytic Capacitors**: These capacitors are polarized and typically used in power supply applications due to their high capacitance values. They are sensitive to voltage and polarity, making proper handling crucial.

2. **Ceramic Capacitors**: Known for their stability and reliability, ceramic capacitors are widely used in high-frequency applications. They are non-polarized and can handle a range of voltages.

3. **Film Capacitors**: These capacitors use a thin plastic film as the dielectric and are known for their low loss and high stability. They are commonly used in audio and power applications.

C. Common Applications of Capacitors in Various Industries

Capacitors are utilized across multiple industries, including telecommunications, automotive, consumer electronics, and renewable energy. Their ability to smooth out voltage fluctuations, filter signals, and store energy makes them indispensable in modern technology.

III. Safety Precautions Before Training

A. Personal Protective Equipment (PPE)

Before engaging in any training involving capacitor equipment, it is vital to ensure that all participants are equipped with appropriate personal protective equipment (PPE):

1. **Gloves**: Insulated gloves should be worn to protect against electrical shocks and to handle components safely.

2. **Safety Goggles**: Eye protection is essential to guard against potential hazards, such as flying debris or chemical splashes from damaged capacitors.