What are the Advantages of Strip Resistor Products?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. Among the various types of resistors available, strip resistors have gained significant attention due to their unique characteristics and advantages. This blog post will explore the advantages of strip resistor products, shedding light on their construction, types, and applications in modern electronics.

II. Understanding Strip Resistors

A. Description and Construction of Strip Resistors

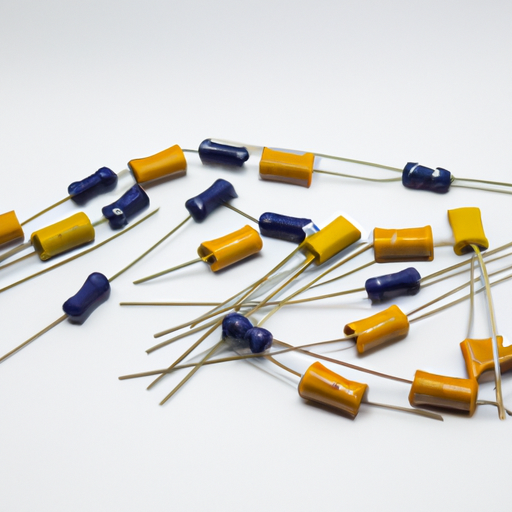

Strip resistors are specialized resistive components characterized by their elongated, flat design. They are typically constructed from a resistive material that is deposited onto a substrate, which can be made from various materials such as ceramic, glass, or polymer. The resistive layer is often created using thin or thick film technology, allowing for precise control over the resistance value.

1. **Materials Used**: Common materials for strip resistors include metal oxides, carbon, and conductive polymers. The choice of material affects the resistor's performance, including its temperature coefficient and stability.

2. **Design Features**: Strip resistors are designed to maximize surface area, which enhances heat dissipation and allows for better thermal management. Their flat profile also makes them suitable for surface-mount technology (SMT), enabling easy integration into compact electronic devices.

B. Types of Strip Resistors

Strip resistors can be categorized into two main types:

1. **Thin Film Strip Resistors**: These resistors are made by depositing a thin layer of resistive material onto a substrate. They offer high precision and low temperature coefficients, making them ideal for applications requiring accurate resistance values.

2. **Thick Film Strip Resistors**: Thick film resistors are created by screen printing a thicker layer of resistive material. They are generally more robust and can handle higher power levels, making them suitable for a wider range of applications.

C. Comparison with Other Resistor Types

Compared to traditional wire-wound or carbon film resistors, strip resistors offer several advantages, including better thermal performance, higher precision, and a more compact form factor. Their design allows for greater flexibility in circuit layouts, making them a preferred choice in modern electronic applications.

III. Advantages of Strip Resistor Products

A. High Precision and Accuracy

One of the standout features of strip resistors is their high precision and accuracy.

1. **Tolerance Levels**: Strip resistors can achieve very low tolerance levels, often as tight as ±0.1%. This precision is essential in applications where exact resistance values are critical, such as in precision measurement devices.

2. **Temperature Coefficient of Resistance (TCR)**: Strip resistors typically exhibit low TCR values, meaning their resistance changes minimally with temperature fluctuations. This stability is vital for maintaining performance in varying environmental conditions.

B. Compact Size and Space Efficiency

As electronic devices continue to shrink in size, the demand for compact components has increased.

1. **Design Flexibility in Circuit Layouts**: The flat, elongated design of strip resistors allows for efficient use of space on printed circuit boards (PCBs). This flexibility enables engineers to design more compact and efficient circuits.

2. **Benefits in Miniaturized Electronic Devices**: In applications such as smartphones, wearables, and IoT devices, where space is at a premium, strip resistors provide an ideal solution without compromising performance.

C. Enhanced Thermal Management

Effective thermal management is crucial in electronic design to ensure reliability and performance.

1. **Heat Dissipation Characteristics**: The larger surface area of strip resistors facilitates better heat dissipation compared to traditional resistor types. This characteristic helps prevent overheating, which can lead to component failure.

2. **Impact on Reliability and Performance**: By managing heat effectively, strip resistors contribute to the overall reliability of electronic devices, ensuring consistent performance over time.

D. Wide Range of Resistance Values

Strip resistors are available in a broad spectrum of resistance values, making them versatile for various applications.

1. **Customization Options**: Many manufacturers offer customization options for strip resistors, allowing engineers to specify exact resistance values and tolerances to meet specific application needs.

2. **Applications in Various Industries**: From consumer electronics to automotive and industrial applications, the wide range of available resistance values makes strip resistors suitable for diverse uses.

E. Improved Stability and Reliability

Stability and reliability are paramount in electronic components, and strip resistors excel in these areas.

1. **Long-Term Performance**: Strip resistors are designed to maintain their performance characteristics over extended periods, reducing the need for frequent replacements.

2. **Resistance to Environmental Factors**: Many strip resistors are engineered to withstand harsh environmental conditions, including humidity, temperature extremes, and mechanical stress, making them suitable for demanding applications.

F. Cost-Effectiveness

While the initial cost of strip resistors may be higher than some traditional resistor types, their long-term benefits often outweigh the initial investment.

1. **Manufacturing Efficiency**: The production processes for strip resistors, particularly thin film technology, can be highly efficient, leading to lower manufacturing costs in high-volume applications.

2. **Long-Term Savings in Applications**: The durability and reliability of strip resistors can result in significant cost savings over time, as they reduce the frequency of replacements and maintenance.

IV. Applications of Strip Resistors

Strip resistors find applications across various industries, including:

A. Consumer Electronics

In devices such as smartphones, tablets, and laptops, strip resistors are used for voltage division, current limiting, and signal conditioning.

B. Automotive Industry

Strip resistors are employed in automotive electronics for applications like sensor signal processing, power management, and control systems, where precision and reliability are critical.

C. Industrial Automation

In industrial settings, strip resistors are used in control systems, robotics, and automation equipment, where their stability and accuracy enhance operational efficiency.

D. Telecommunications

Telecommunication equipment relies on strip resistors for signal integrity and power management, ensuring reliable communication in various applications.

E. Medical Devices

In the medical field, strip resistors are used in diagnostic equipment, monitoring devices, and therapeutic instruments, where precision and reliability are paramount for patient safety.

V. Challenges and Considerations

While strip resistors offer numerous advantages, there are also challenges and considerations to keep in mind.

A. Limitations of Strip Resistors

Strip resistors may not be suitable for all applications, particularly those requiring very high power ratings or extreme environmental conditions. Understanding the limitations is essential for proper application.

B. Factors to Consider When Selecting Strip Resistors

1. **Application Requirements**: Engineers must consider the specific requirements of their application, including resistance value, tolerance, and power rating.

2. **Environmental Conditions**: The operating environment can significantly impact resistor performance. Factors such as temperature, humidity, and mechanical stress should be evaluated when selecting strip resistors.

VI. Conclusion

In summary, strip resistors offer a range of advantages that make them an essential component in modern electronics. Their high precision, compact size, enhanced thermal management, and wide range of resistance values contribute to their growing popularity across various industries. As technology continues to evolve, the demand for reliable and efficient components like strip resistors will only increase.

Looking ahead, advancements in strip resistor technology are likely to focus on improving performance, reducing costs, and expanding their applications. As engineers and designers continue to push the boundaries of electronic design, strip resistors will remain a vital part of the equation, ensuring that devices operate reliably and efficiently in an ever-changing technological landscape.

VII. References

1. "Resistor Technology: A Comprehensive Guide," Electronics Weekly.

2. "Understanding Resistor Types and Their Applications," IEEE Spectrum.

3. "The Role of Resistors in Electronic Circuits," Journal of Electronic Materials.

4. "Advancements in Thin Film Resistor Technology," Journal of Applied Physics.

5. "Thermal Management in Electronics: Best Practices," Electronics Cooling Magazine.

This blog post aims to provide a comprehensive overview of the advantages of strip resistor products, highlighting their significance in various electronic applications while addressing potential challenges and considerations for their use.